Brown Film Faced Plywood Sheet with Logo Words

| Min. Order: | 60 Cubic Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 360 Cubic Meter / Day |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Brown Film Face Plywood Sheet, Black Film Faced Plywood Sheet, Okume Commercial Plywood Sheet, Bingtangor Commercial Plywood Sheet |

Product Detail

| Model No.: | QDGL140923 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | GOLD LUCK |

| Size: | 1220x2440mm, etc. |

| Core: | Poplar, Combi, Hardwood, etc. |

| Glue: | MR, Melamine, WBP, etc. |

| Thickness: | 9mm-25mm |

| Film: | Black, Brown, Red, etc. |

| Quality: | One time hot press; Two times hot press |

| Moisture Content: | 8% |

| Glue Bond Strength: | 0.80-1.35 MPa |

| Origin of Production: | Shandong, China |

| Delivery Time: | Within 7 days after deposit |

| Production Capacity: | 360 Cubic Meter / Day |

| Packing: | 18plts/40HQ 16plts/40GP 8plts/20GP |

| Delivery Date: | Within 7 days after receiving down payment |

Product Description

Product Specifications of Film Faced Plywood

Product Overviews

| 1) Size: | 1220 × 2440mm, etc. |

| 2) Thickness: | 9mm ~ 18mm |

| 3) Core: | Poplar, Combi, Hardwood, etc. |

| 4) Film: | Black, Brown and Red film; etc. |

| 5) Glue: | MR, MLM, WBP, etc. |

| 6) Quality: | One time hot press; Two times hot press, etc. |

| 7) Frequency of use: | above 15 times (Two times hot press) |

| 10 ~ 15 times (One time hot press) | |

| 5 ~ 10 times (Finger joint) |

Specifications

| 1) Moisture Content: | 8 ~ 10% |

| 2) Glue Bond Strength: | 0.80 ~ 1.35 MPa |

| 3) Static Bending Strength: | along the grain 55 MPa |

| across the grain 38 MPa | |

| 4) Modulus of Elasticity: | along the grain 6578 MPa |

| across the grain 4942 MPa | |

| 5) Density: | poplar core 500 KGS/CBM |

| combi core 500-700 KGS/CBM | |

| hardwood core above 700 KGS/CBM |

Production Process of Film Faced Plywood

Packaging and Shipping Ways

of Film Faced Plywood

Loading In Container

Loading In Bulk

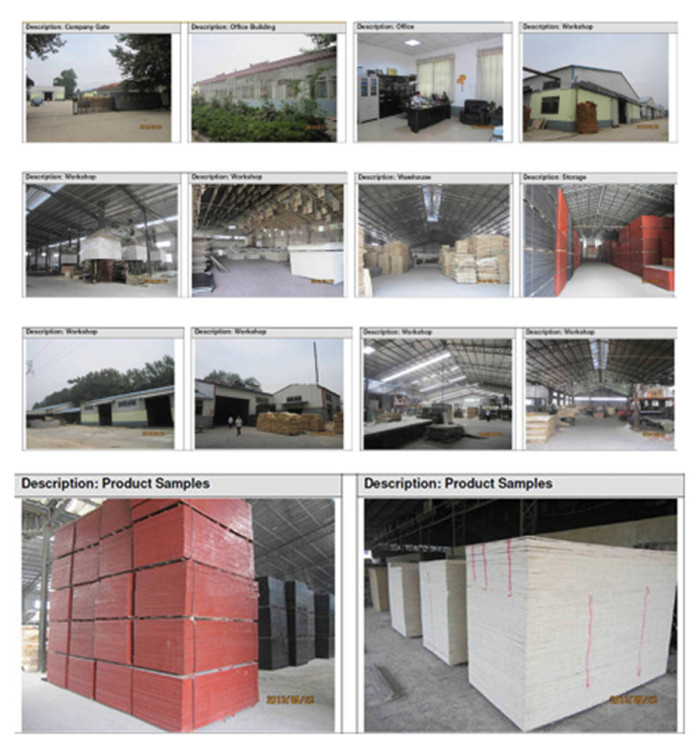

Company Information

1) 12 years plywood production experience.

2) 12 production lines.

3) Daily output: 6x40HQ.

4) Anuual export: 200 million USD or so.

5) Delivery Time: within 7 days after 30% deposit

FAQs of Film Faced Plywood

1) Bonding strength is low:

Is mainly caused by poor quality plastic. Hot press conditions are not controlled well, such as low pressing temperature, low pressure, and too short pressure time. Those will lead to low bonding strength. Too high veneer moisture content, insufficient amount of glue, poor quality veneer and too long or too short veneer assembly time, will also reduce the bonding strength.

2) Bubbling and local delamination:

The reason lies in too fast pressure relief, lack of pressure time, too high veneer moisture content, blank spots on the board during gluing or inclusions and dirt on the veneer, etc.

3) Plywood warp:

Is due to large internal stress within plywood. The reason is that the moisture content of face and back veneer is inconsistent with each other: different species veneer mismatches unreasoningly; veneer texture distortion; individual hot pressure temperature is not enough; plat piled unevenly; etc.

4) Delamination of edges and corners:

The reason is mainly caused by insufficient pressure that the press plate's edges and corners of hot press machine is worn; slabs in each interval of hot press machine is not aligned in edges and corners; when putting slabs in each interval of hot press machine, too skewed, so uneven pressure happens; when rotary cut, edges of veneer is insufficiently pressed; adhesive tension is weak; corners and edges are lack of glue; glue dries prematurely; temperature of localized place on pressure plate is low; etc.

5) Glue penetration:

The reason is that the lowsolids content of glue, excessive usage amount of glue, deep cracks on the back of the veneer, too high moisture content of veneer, too long veneer assembly time and too high pressure of hot press machine, and so on.

6) Excessive formaldehyde emission:

Is related with quality of glue, gluing process, etc.

Buyer Tips of Film Faced Plywood

1) Firstly, usage and personal preferences decide the choose of differ wood species, patterns and colors of plywood. Apperance quality of plywood directly affects the effects in use. Face of plywood should not have damages, bumps, rot, knots, cracks, indentation, dirt, rough and other defects. Requirementsfor back of plywood is generally less strict.

2) To choose the plywood that its layers of veneer are spliced tightly, no stack or no open joint.

3) When receiving plywood, it needs to measure the actual thickness of the plywood if it is consistent with what sellers promised to prevent cutting corners.

4) Attention to the glue bonding quality of plywood is needed. To choose the plywood with stable layer structure and no delamination. When purchasing, we use our hands to knock all parts of plywood. If crisp sound, quality of plywood is usually good; if muffled sound, it always indicates poor glue bonding quality. Also, we can use knife to pry plywood to text its glue bonding quality, i.e. to pry plywood layer with a sharp blade. If glue line is destroyed but wood is not, it shows the glue bonding quality of plywood is poort.

5) To choose environmentally friendly plywood. Do not buy the plywood with clear pungent odor.

Certificates of Film Faced Plywood

115Th Canton Fair Show

Our Services