Alloy Wheel Powder Coating Spray Machine

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 200Piece/Pieces Per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | CL-171S |

|---|---|

| Means of Transport: | Ocean, Air |

| type: | Coating Spray Gun |

| weight: | 50kgs |

| Dimension(L*W*H): | 120*80*80 |

| Material / Metal: | Steel,all metallic surface |

| Voltage: | 220v/110v |

| Power(W): | 50W |

| Certification: | CE/ISO |

| After-sales Service Provided: | Overseas service center available |

| Warranty: | 1 YEAR |

| Production Capacity: | 200Piece/Pieces Per Month |

| Packing: | wood box or carton box |

| Delivery Date: | 15 days |

Product Description

Alloy Wheel Powder Coating Spray Machine.

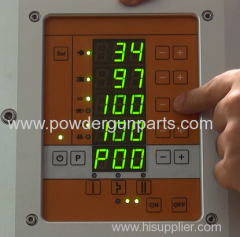

The colo-171s has good performance on powder coating alloy wheels, even the awkward corners or thin ribs, the powder coating machine achieves complete and uniform coated surface. The perfect results derived from the intelligent and advanced gun controller, the DVC technology(Digital Valve Control) allows users setting accurate electric and pnuematic data to make a precise powder output.

The features of the powder coating gun controller

1) 3 presetting model for beginners, flat coating, complex coating, repeat coating.

2) Create and store 20 different coating programs for experienced users.

3) Precisely adjust kv, powder output, supplementary by pressing the "-" and "+" buttons

The advantages of the manual spray gun

1)Optimal design to reduce operator's fatigue

2)100kv cascade for long lasting work

3)High quality material without powder stick.

4) Flat nozzles and round nozzles for different shaped parts.

Specifications of Powder Coating Machine

Model | COLO-171S Powder Coating Spray Machine |

Power range | 220/110V 1 Phase (customized ad local) |

Frequency | 50HZ |

Temperature range in use | -10 ℃+50 ℃ |

Powder Gun | |

Gun weight: … | 500G |

Rated output voltage | 24VDC |

Maximum output current | 180Ua(max) |

Maximum output voltage | 0-100KV ( adjustable) |

Maximum powder injection : | 600g/min |

Polarity | negative (-) |

Pneumatic data | |

Maximum input-air pressure | 10kg/cm |

Optimum input-air pressure | 6kg/cm |

Minimum input-air pressure | 4kg/cm |

Maximum water vapor content or compressed air | 1.4g/N m3 |

Maximum oil vapor content of compressed air | 0.1ppm |

Maximum compressed-air consumption | 13.2 m3/h |

Why choose powder coating machine?

1) Powder coated parts is non-toxic, good for humans health

2) The coated surface is more durable and wear-resistance.

3) Achieves more superior appearance of metal parts

4) The remaining powders can be recycled to reduce consumption