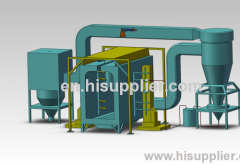

cyclone powder spray booth

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 3pcs per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | COLO-S |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | colo |

| CLEAN: | easy clean -up |

| Powder Coating Booth: | Cyclone Recovery |

| powder booth: | automatic powder coating |

| size: | custom-made |

| Delivery time: | 15-25days |

| Warranty: | 12months |

| After-sales Service Provided: | Overseas service center available |

| Certification: | CE and ISO |

| Protection Type: | IP54 |

| payment way: | 50% in advance, 50%before shippment |

| Production Capacity: | 3pcs per month |

| Packing: | wood box |

| Delivery Date: | 15-25days |

Product Description

cyclone powder spray booth

Ideally suitable for big automatic plants where quantity of powder to be sprayed and recovered is high.

Summary of Benefits :

1,Excellent overall filter clean function, last the filter use life.

2,Stable recycle the air flow, make sure the cyclone separator function

3,Low air consumption, low noice.

4,Low operation cost

5,High quality special material filters

6,Multi-Cyclone recovery system ensures extremely high levels of powder recovery 98% .

7,Faster Color Change:The Bottom of the Booth prevents accumulation of the powder and makes it very easy for cleaning and quick Color change. The powder coating booth is very easy to clean,and fast color change only in 20 minutes.

8,including the dustproof lights.

9,Superior ability to control the air flow, make sure the highly efficiency of powder.

10,Fast connect with the recovery system.

11,Unique Euro Style designing.

12,Combined type designing, layout flexible

Integrated Powder Hopper and filter available can be bought as an optional items. |

Technical data:

No. | Booth type | automatic powder coating booth with two recovery system |

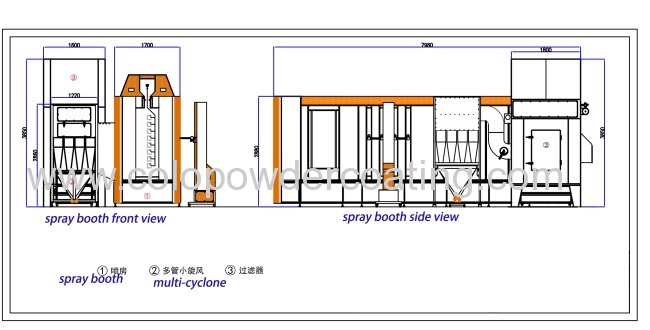

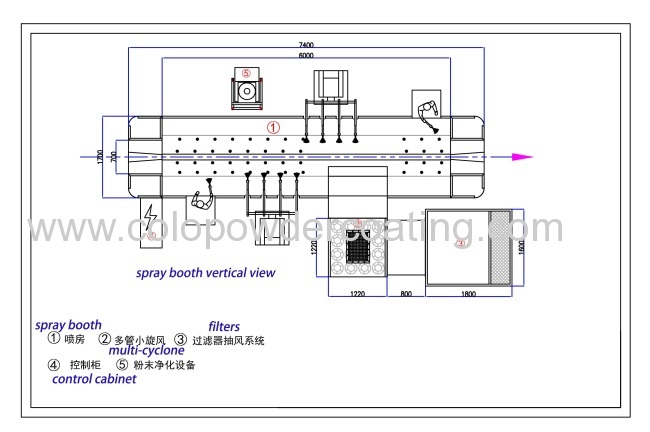

1 | Inner size of powder room: | 6000mm×1700mm×2880mm(refer to layout)(1set) |

2 | Material of powder room: | side\top\bottom board: δ1.2mm galvanized board (surface spraying) |

3 | Inverter lift | 2sets |

4 | Closed-circuit system | 1set |

5 | Automatic electrostatic sprayer: | 8sets |

6 | Manual sprayer | 2sets |

7 | 9 cores recycling of the upper and lower device | 1(hot plate and cold plate to make) the height of filter:660mm |

8 | Recover fan | 1sets(15Kw)air volume:20000m3/set

|

9 | 9 pcs cyclone | 1(A3 plate T1.5mm to make) |

10 | Explosion-proof fluorescent lamp; | Each 1 piece of unilateral |

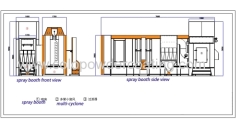

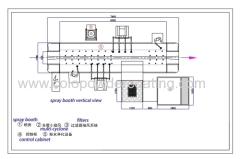

Drawing:

The instruction of the spray booth

The details of the powder coating booth:

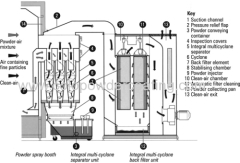

Automatic powder spray booth overall program description:

This is a multi-tube small whirlwind two recycling automatic spray systems, spray booths made of stainless steel plate, spray booth design has eight automatic guns, two hand guns openings.

a. system configuration 8 total automatic spray gun, using double order.

b. Multiple small cyclone technology used in Europe, the recovery rate can reach 95% or more, and is equipped with automatic opening and closing device for easy cleaning,

c, after the turn-wing filter uses filter recovery, high efficiency, low noise.

d. spray booth made of high quality anti-static stainless steel plate.

e. equipment with automatic recovery and sifting system to ensure the normal powder-polluting cycle.

f. equipment with high efficiency, low environmental fan.