Cyclone recovery powder booth

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T, WU |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Brand Name: | colo |

| Condition: | new |

| type: | Coating Production Line |

| Substrate: | Aluminum |

| coating: | painting |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Warranty: | 12months |

| Certification: | ISO9001/CE |

| Voltage: | 380V/110V/220V |

| Power(W): | 5.5KW |

| Dimension(L*W*H): | customized as you want |

| Packing: | wood box |

| Delivery Date: | 35dyas |

Product Description

What do you need to get Powder Coating?

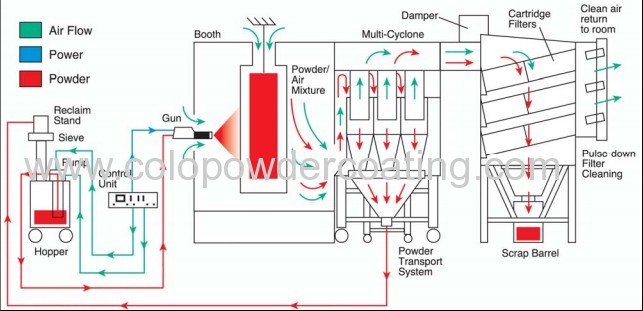

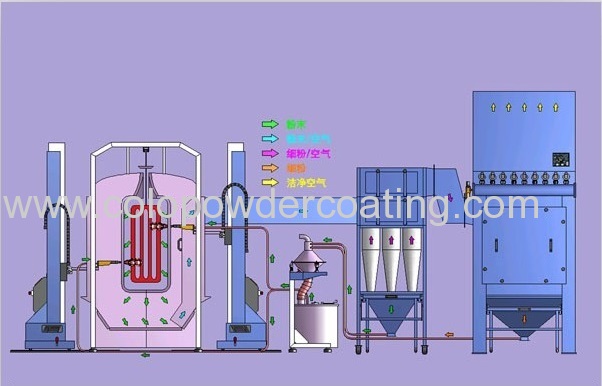

Spraybooth:

The first requirement of any Powder Coating System is a

Spraybooth in which to apply the Powder. This serves a number of functions:

1) It ensures that oversprayed Powder is ventilated away from the Operator(s)

2) It provides extraction to prevent Powder escaping into the factory areas

3) It collects the Powder and can provide facility for reclaiming overspray Powder

Curing Oven : All Powders cure at high temperatures, usually between 160 and 220 Centigrade. Therefore an Oven is required to place the parts after they have been sprayed.

Powder Spraying System:

The Spraying System is the device that applies the Powder. This is often called the 'Powder Gun' and serves the following functions:

1) It has a system for storing new and recycled P owder,often this may be the Box in which it is delivered from the supplier.

2) It fluidises the Powder i.e. it gently blows air into the Powder, effectively bestowing it with the characteristics of a liquid.

3) It has a nozzle system which allows the Powder to be blown onto the product.

4) It has an Electrostatic charging system which charges the Powder Particles causing them to be attracted to the part requiring coating.