new powder coat booth

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 200Piece/Pieces Per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

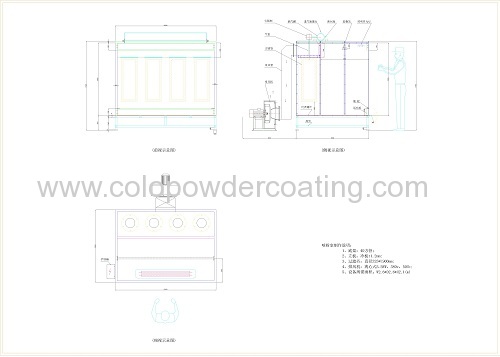

| Model No.: | COLO-S |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | colo |

| Type: | Coating Production Line |

| weight: | 300kgs |

| Filters hang type: | Bagnet type, easy on/off. |

| Dimension(L*W*H) external: | L2080×W1500×H1840mm |

| Material / Metal: | Steel,all metallic surface |

| Voltage: | 380V/415V |

| Power(W): | 5.5KW |

| Certification: | CE/ISO |

| After-sales Service Provided: | Overseas service center available |

| Warranty: | 1 YEAR |

| Production Capacity: | 200Piece/Pieces Per Month |

| Packing: | wood box or carton box |

| Delivery Date: | 15 days |

Product Description

side view

side view pulse valve

pulse valve side view

side view

1.what is powder coating

powder coating booth

Powdercoating is a type of coating that is applied as a free-flowing, drypowder. The main difference between a conventional liquid paint and apowder coating is that the powder coating does not require a solvent tokeep the binder and filler parts in a liquid suspension form. Thecoating is typically applied electrostatically and is then cured underheat to allow it to flow and form a "skin". The powder may be athermoplastic or a thermoset polymer. It is usually used to create ahard finish that is tougher than conventional paint. Powder coating ismainly used for coating of metals, such as household appliances,aluminium extrusions, and automobile and bicycle parts. Newertechnologies allow other materials, such as MDF (medium-densityfibreboard), to be powder coated using different methods.

2.The advantage of powder coating over conventional liquid coatings:

Powder coatings emit zero or near zero volatile organic compounds (VOC).

Powder coatings can produce much thicker coatings than conventional liquid coatings without running or sagging.

Powder coating overspray can be recycled and thus it is possible to achieve nearly 100% use of the coating.

Powder coating production lines produce less hazardous waste than conventional liquid coatings.

Capital equipment and operating costs for a powder line are generally less than for conventional liquid lines.

Powdercoated items generally have fewer appearance differences betweenhorizontally coated surfaces and vertically coated surfaces than liquidcoated items.

A wide range of specialty effects is easily accomplished which would be impossible to achieve with other coating processes.

3.The process of powder coating

Part preparation or the pre-treatment

The powder application

Curing

4.The powder coating equipments we produced:

1.Electrostatic powder coating machine

2.Powder coating spray booths

3.Powder coating curing oven

4.Manual powder coating line

5.Semi-automatic powder coating line

6.Full automatic powder coating line

7. reciprocating machine

8.Seiving machine

5.Powder coating line custom made:

If you want to custom made any powder coating line,pls tell us the following specifications:

1.The size of workpiece,especially the largest size

2.The biggest weight of the workpiece

3.If have any requirements about the suspension of the workpiece

4.The material of the workpiece

5,The anticipative output for the biggest size of the orkpiece(how many pcs in 8 hours)

6.The length,width and height of the factory available for the powder coating line

7.The heating power:Liquefied Petroleum Gas, Liquefied natural gas,diesel,or electric.

8.If need to change colors in one day?How many colors do you have?

9.Need automatic paint or manual paint

10. If need pretreatment process?If need,want spray pretreatment or bath pretreatment?

11. The local electricity conditions(V/PHASE/HZ)

12. If have any special requiremnts about the package?

We could make the design according customer's requirements.Pls contact with me and we will give you the quick reply.