Electrostatic powder coating line with ISO9000 quality management system

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 200Piece/Pieces Per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | COLO-L |

|---|---|

| Means of Transport: | Ocean |

| line: | powder coating |

| Extra Services: | Painting / Powder Coating |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal: | Aluminum |

| product max size: | L500mm*W600mm*H900mm |

| product max weight: | ≤30Kg |

| Conveyor chain single hanging weight: | 20 Kg |

| Design line speed and adjustable line speed: | 1.5m/min (0.3m-3.6m/min) |

| Compressed air: | the users themselves, freeze-drying, moisture content <1.3g/m3 oil content <1PPM |

| Production Capacity: | 200Piece/Pieces Per Month |

| Packing: | wood box or carton box |

| Delivery Date: | 15 days |

Product Description

Specifications

electrostatic powder coating line many years experience in this field

worldwide shipping avaiable

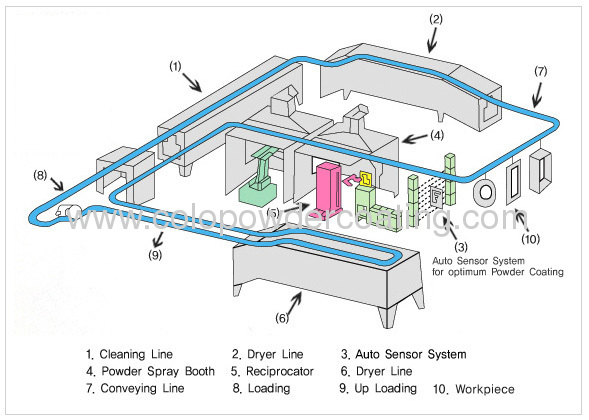

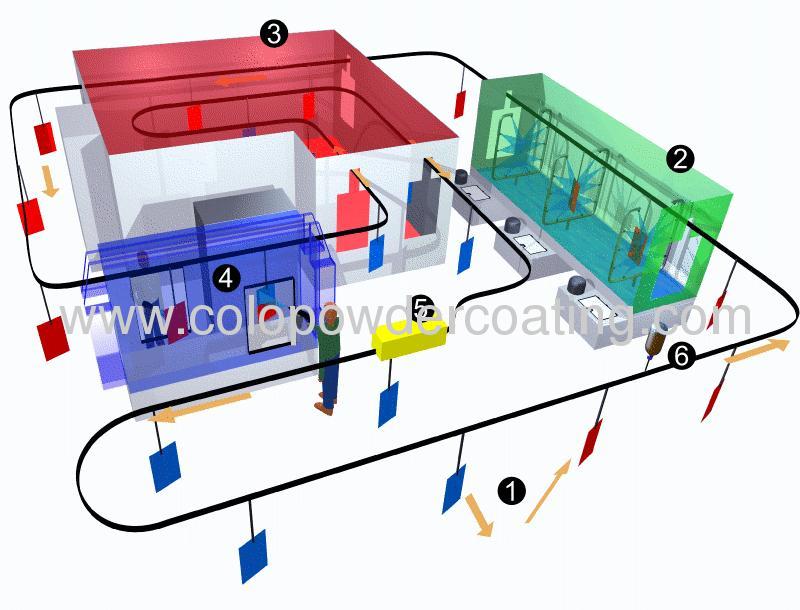

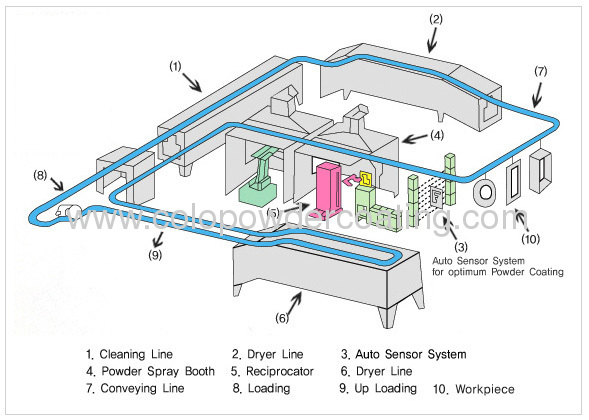

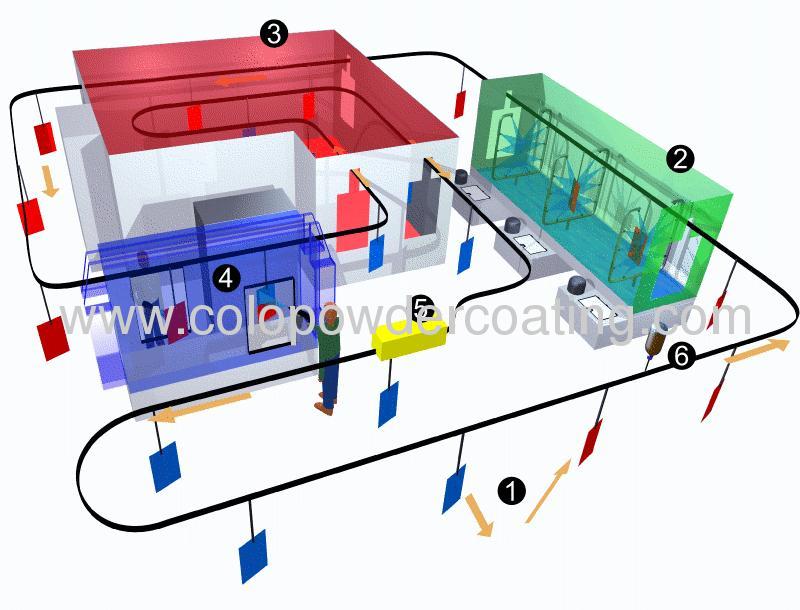

Electrostatic powder coating line

Hangzhoucolor powder coating equipment Co.,LTD isthe leading manufacturer whospecialized in the powder coating equipments in China, includingpretreatment (both economical immersion tank type and auto verticalshower type), dry-off furnace, powder booth, powder guns, reciprocator,recycling unit for over-spray powder, curing furnace, etc. Our coatinglines are suitable for aluminium profiles, control cabinets, aluminiumwheels, LPG tanks, hardware, iron chairs, dish antennas, wire meshs,fences, crash barriers, guide railings, and so on. We're able to providethe surface treatment equipments on nearly all aluminium and steelworkpieces.

Safe & Firm sandwich panel structure made of engineeringplastics, offering easy cleaning operation & high powder coatingratio on work piece.

Safe & Firm sandwich panel structure made of engineeringplastics, offering easy cleaning operation & high powder coatingratio on work piece.

-Powder saving, cyclone separation efficiency 98%.

-Booth bottom automatic cleaning unit, preventing powder from depositing in the bottom of paint booth.

-Automaticallyrecovery from powder feed center with Pulse Airflow for cleaning powdersuction pipe, powder pump and paint gun pipe.

-Addition of new powder feed device to enable auto feeding & mixing rate for old & new powder.

-Saving powder design, minimum wasting of powder fluidization.

-Addition of auto cleanup device of paint gun for your convenience