leading equipment painting companies in China

900.0~1500.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 5000 sets/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | colo-PGC1 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | COLO |

| type: | Electrostatic Spraying Equipment |

| Certification: | CE |

| Method Type: | manual |

| Application: | Plastic Spraying Equipment |

| Pulse: | electrostatic |

| Export Markets: | global |

| Production Capacity: | 5000 sets/year |

| Packing: | paper carton or wooden carton |

| Delivery Date: | 2-10 days |

Product Description

powder spray unit of powder coating system ,used for manual powder coating,for spraying metallic products.

Advantage

0-100 Digital Adjustable KV

Fully Adjustable Amperage

PGC1 Control Unit with PG1 powder coating gun

Fully Adjustable Air for Pump on Pressure, Dosage and Nozzle Rinsing Air.

Comes with Full Array of Nozzle Assortment.

Field Tested and Proven to operate in the toughest environments.

Comes with different array of delivery systems:

Hopper Feed - 45L

Fully Adjustable Amperage

PGC1 Control Unit with PG1 powder coating gun

Fully Adjustable Air for Pump on Pressure, Dosage and Nozzle Rinsing Air.

Comes with Full Array of Nozzle Assortment.

Field Tested and Proven to operate in the toughest environments.

Comes with different array of delivery systems:

Hopper Feed - 45L

this system is specially balanced for the maximum spray capability with

the Smoothest Finish Possible.

the Smoothest Finish Possible.

Manual powder gun

--INSTALLATION

→Propery ground all equipment in the spray area to an earth ground and maintain this ground

→Remove all containers of volatiles from the spray area

→Establish and maintain a grounded area for the spray operator

→The gun of x series must be connect to x control unit

→OPERATION

→The operator should hold the gun in his bare hand

→If gloves are worm ,the palm should be out to assure skin to metal contact

→The operator should wear shoes with conductive shoes e.g leather

Rubber shoes are not conductive .

→Ground the tip of the gun before cleaning or changing nozzles.

→When the gun is not in use , it should be hung so that the nozzle is within four inches of a grounded conductor

→The operator should wear a filter-type respiator anytime he is exposed to dusty conditions

→High pressure powder many cause injury ,Keep the rear switch "off" position in no –use condiction

→MAINTENANCE

→Make a periodic confirmation of grounding to earh of all equipment in the spray area .

→Exercise good housekeeping practices , do not allow dirt or powder to accumulate on the feeder /powder unit , cable or gun.

→Keep the cabinet door

PERSONNEL

→Use soap and water to remove powder from the skin washing with solvents can cause reactions resulting in allergies and disourders.

→Wash hands before eating and smoking.

→Do not use compressed air to blow powder off the hands and clothing.

This practice may result in damage to the ear drums or eyes.

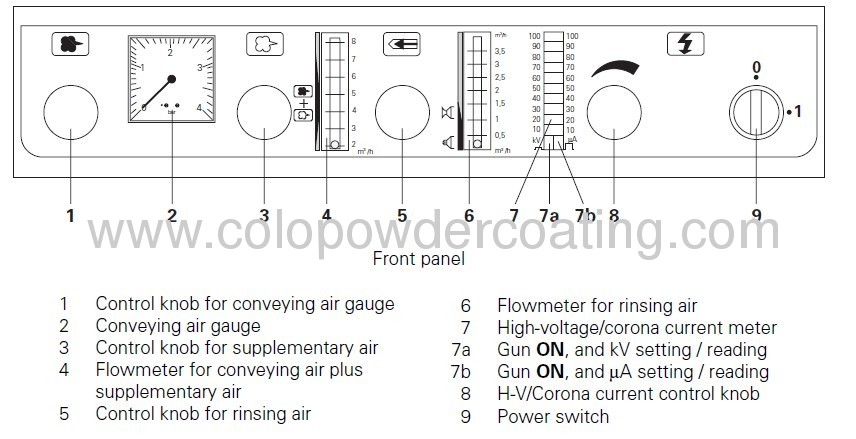

Manual coating equipment Function description

the powder gun through the powder hose . The powder is electrostatically

charged at the nozzle of the gun. In addition, an electrostatic field is

created between the gun nozzle and the grounded object. The charged

powder spray remains adhered to the surface of the object.

The powder is fluidized by air forced through a porous plastic plate from

below. The powder acquires, thereby, fluid-like characteristics.

The conveying air, supplementary air, and rinsing air are set on the control

Unit

| Electrical data | ||

| Mains input voltage | 100-240 VAC | |

| Operating frequency | 50-60 Hz | |

| Input power | 50W | |

| Nominal output voltage (to the gun) | max. 12 V | |

| Nominal output current (to the gun) | max. 1 A | |

| IP54 | ||

| Ambient temperature range | 0°C - +40°C (+32°F - +104°F) | |

| Max. operating temperature | 85°C (+185°F) | |

| Approvals | CE | |

| Pneumatical data | ||

| Compressed air connection | 1/4" male quick release | |

| Max. input pressure | 10 bar / 145 psi | |

| Min. input pressure (while unit in operation) | 6 bar / 87 psi | |

| Max. water vapor content of the compressed | air 1.3 g/m³ | |

| Max. oil vapor content of the compressed air | 0.1 mg/m³ | |

| Packing Dimensions | ||

| Length | 120CM | |

| Width | 79CM | |

| Height | 73CM | |

| Weight | approx. 55kgs | |

| Connection Description | ||

| 1.1 Air In | Compressed air connection (6-10 bar / 87-145 PSI) | |

| 2.1 Power | Mains cable connection (100-240 VAC) | |

| 2.2 Gun | Gun cable connection | |

| 1.4 |

| |

| 1.3 | Pict

| |

| 1.2 | Pict

| |

| Grounding connection | Pict |

Include

A control unit power supply cable

- A air filter

- A air pressure regulator

- A fluidized powder hopper

- A plug-in injector

- An manual powder gun with gun cable, powder

hose, rinsing air hose and standard nozzle set.

- Pneumatic hoses for conveying air (red), supplementary

air (black) and fluidizing air (black)

powder hose

Ground wire