Burn-Off Ovens for Cleaning Paint Line

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 200Piece/Pieces Per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Automation: | Automatic |

| Extra Services: | Painting / Powder Coating |

| Certification: | CE |

| Burn-Off Ovens: | for Cleaning Paint Line Components |

| Production Capacity: | 200Piece/Pieces Per Month |

| Packing: | wood box or carton box |

| Delivery Date: | 15 days |

Product Description

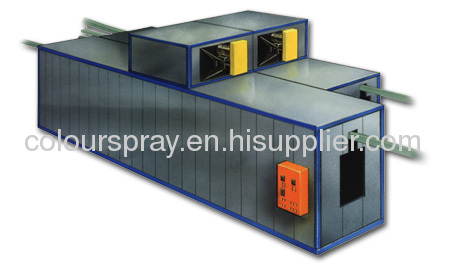

BURN-OFF OVENS FOR CLEANING

While there are a number of ways to keep paint line components clean, theburn-off oven has become a standard in many facilities due to the ability toclean many parts at once with little or no pollution or hazardous waste. Otheradvantages are: minimal labor, energy efficiency, and quick turnaround. In-housecleaning allows for more control, less damage to parts, less need for duplicateracks and time saved from packing/unpacking parts for outside cleaning. Burn-offovens provide an easy and efficient method for cleaning many different sizes ofparts as well as sensitive reject parts such as aluminum and thin sheet steel.Operating costs can be quite low as some ovens are particularly energyefficient.

Burn-off oven processing produces clean parts, resulting in a much moreefficient coating system. Parts are typically cleaned more often when a burn-offoven is installed in house. Overspray is minimized and coating quality isimproved. Waste disposal, labor, material and transportation costs are allreduced leading to higher productivity and profitability.

Ovens of all sizes and configurations in all price ranges for all your powder coating needs