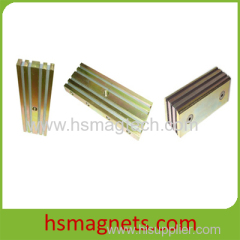

Neodymium Various Holding Magnetic Assemblies

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, PAYPAL, T/T, WU |

| Supply Ability: | 1000000000 PCS |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Magnet, Permanent Magnet, Sphere Magnet |

Product Detail

| Model No.: | Holding-4 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Industrial Magnet |

| Shape: | Others |

| Type: | Permanent |

| Composite: | Rare Earth Magnet |

| Brand Name: | HSMAG |

| Material: | Sintered Ndfeb |

| Size: | according to customers' request |

| Application: | Suitable for transferring cast ingots, steel balls, metal and steel scraps. The electromagnet can be fitted on excavator |

| Certificate: | ISO9001:2008, SGS test report |

| Shipment Term: | Usually bysea or by air or by express |

| Shape: | block |

| Production Capacity: | 1000000000 PCS |

| Packing: | High quality cartons or according to customers' requirements |

| Delivery Date: | 7-15 days |

Product Description

NdFeB Magnetic Outsanding product:

1). High performance: N52, N48M, 48SH, 42UH, 38EH, 33AH

2). High working temperature: The AH series with 40 k Oe super-high coervice force can replace SmCo magnets successfully.

3). High consistency: The cpk of Br and Hcj are much higher than 1.67 the consisitency of surface magnetic field and magnetic flux can be controlled with +/-1%

4). High Anti-corrosion: The sale spray test and humid heat test of the high anti-corrosion coating could be more than 1000 hours

5). Low weight loss

PCT: 130c, humidity 100%, vapor pressure 2.7 bar. 20 days, average low weight loss less than 2 mg/cm2

NdFeB Magnetic applications:

Loudspeakers, motor assemblies, windmill, Home appliance, acousics, communication equipment, toy, car, servomotor, step motor, DC motor and linear motor, mircrophones

Pros: Very strong hold when contacting another magnet or plain iron, very difficult to pull away (easy to slide however).

Pretty strong hold between two of these even with a couple of mm in between.

Cons: Would like thicker (and more powerful) versions. Sure u can stack these together but sometimes it's not the same thing.

Other Thoughts: Good for attaching thick stacks of paper to refrigerators etc or pinching together papers or textiles.

Bottomline: This is the one if you need strong cost-effective magnets

PCT:130c ,humidity 100%,vapor pressure 2.7 bar.20 days,average low weight loss less than 2 mg/cm2

Common Applications :

Sensors Linear actuators Microphone assemblies Magnetic separators DC and servo motors Speakers Printers Magnetic hooksComputer rigid disc drives Beam controls Intelligent toys MRI/NMR

We are specialized in producing NdFeB Magnet over many years,We guarantee the best price based on the same quality and service. Our finance conditiearon and industrial reputation are excellent.

Testing Center

We are ISO/TS16949:2002 certified and well implement all procedures strictly under control. Problem preventive actions and quality assurance are preoperly combined with special inspection for all procedures from raw material purchasing ,outside cooperating part manufacturing,inside manufacturing to shipping . We also install a complete set of physical and chemical test equipment to make sure that all our products are manufactured and shipped under strictly quality control .

Salt Spray Test :

Mainly test the surface treatment against the corrosion. Usually the tested samples will be continuous sprayed 24 hours in the 35℃ temperature to see if there is any rust appearance on the surface.

Projection Instrument:

Mainly test the magnets with irregular shapes such as arc segments and any other irregular-shaped parts to see if their dimensions meet the customers' requirements or not.

PCT Instrument:

Mainly test the magnets to prevent against corrosion on the high temperature and high atmospheric pressure . Usually the test condition is 120℃ temperature and 2 atmospheric pressure .

Heat& Humidity Instrument:

Mainly test the magnet to against corrosion on certain temperature and humidity . Usually the test condition is 80℃ temperature and 90%+/-3% humidity

Hysteresgraph:

Mainly test the magnetic characteristics of the magnet, including Residual (Br ), Coercive(Hcb) . Intrinsic Coercive(Hcj), Max. Energy product(BH max) and any other related magnetic parameters.

HSMAG Magnets has been supplying high quality Neodymium Magnets to customers for about 20 years.

Made of neodymium, the most powerful magnet material in the world

Great for projects that require extreme strength in a small size

Permanent magnetism guaranteed

Not for children