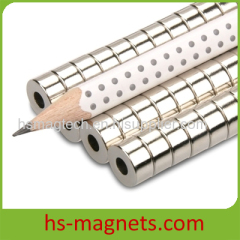

Sintered Ring NdFeB Permanent Magnet

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, PAYPAL, T/T, WU |

| Supply Ability: | 1000000000 PCS |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Magnet, Permanent Magnet, Sphere Magnet |

Product Detail

| Model No.: | RING-7 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Shape: | Ring |

| Application: | Speaker Magnet |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | HSMAG |

| Material: | Sintered Neodymium-Iron-Boron |

| Size: | according to customers' request |

| Coating: | Ni-Cu-Ni / Zinc / Glod / Epoxy |

| Application: | sensors,motors, rotors,wind turbines,wind generators |

| Certificate: | ISO9001:2008, SGS test report |

| Shipment Term: | Usually bysea or by air or by express |

| Shape: | block/ cube/ rectangular/ sheet |

| Grade: | N35-N52,33M-48M,33H-48H,30SH-45SH,30UH-38UH and30EH-35EH |

| MAX Temperature: | 200 °C |

| Production Capacity: | 1000000000 PCS |

| Packing: | High quality cartons or according to customers' requirements |

| Delivery Date: | 7-15 days |

Product Description

1. Specification of Neodymium Magnets:

Chemical composition: Nd2Fe14B.

Neodymium magnets are hard, brittle and easily corrode.

2. Moderate temperature stability

Neodymium magnets lose -0.09 ~ -0.13% of Br/°C.

Their working stability is under 80°C for low Hci Neodymium magnets and above 200°C for high Hci Neodymium magnets.

3. Excellent strength value

High magnetic performance (Br: 11,000 to 14,500 GS, Hcj: 11,000 to 30,000 Oe, BHmax: 35 to 50 MGOe)

4. Advanced Technology

The choice of Strip casting and HDDR technology in our factory allows us to make high performance Neodymium Magnets of N52 possible. The standard properties, N33, N35, N38, N40, N42, N48, N50, N52 (M, H, SH, EH, UH)

5. Extremely resistance to demagnetization

The intrinsic coercive force is over 30,000 Oe, like N35EH and N38EH property. Maximum working temperature: 80 to 200 centigrade. Super strong magnetic force and high intrinsic coercive force and also with precise tolerance

6. Effective surface treatment

Surface treatments have been developed that allow them to be used in most applications. The treatments include Ni, Ni-Cu-Ni, Zn, Ag, Au and other special plating. They are good at anticorrosion.

7. Customized Neodymium Magnets

Most of our magnets are customized. They are produced for customers' specific using, like arc, tile, square, cylinder and magnetic ring with various sizes. Common specification samples will be available in stock for your testing first.

8. Applications

Security systems, Magnetic separators, Magnetic resonance imaging, Health bandages and plasters, Specialty door catches, Filters & strainers, Sensors, Speakers, Microphones/earphones, High performance motors, Brushless motors, Micro motor, servo motors, VCM(voice coil motor), Automobiles, Magnetic couplings, Magnetic Chucks, Magnetic toys, Magnetic tools, Other magnetic applications

9.Performance of Neodymium magnets

Testing Center

We are ISO/TS16949:2002 certified and well implement all procedures strictly under control. Problem preventive actions and quality assurance are preoperly combined with special inspection for all procedures from raw material purchasing ,outside cooperating part manufacturing,inside manufacturing to shipping . We also install a complete set of physical and chemical test equipment to make sure that all our products are manufactured and shipped under strictly quality control .

Salt Spray Test :

Mainly test the surface treatment against the corrosion. Usually the tested samples will be continuous sprayed 24 hours in the 35℃ temperature to see if there is any rust appearance on the surface.

Projection Instrument:

Mainly test the magnets with irregular shapes such as arc segments and any other irregular-shaped parts to see if their dimensions meet the customers' requirements or not.

PCT Instrument:

Mainly test the magnets to prevent against corrosion on the high temperature and high atmospheric pressure . Usually the test condition is 120℃ temperature and 2 atmospheric pressure .

Heat& Humidity Instrument:

Mainly test the magnet to against corrosion on certain temperature and humidity . Usually the test condition is 80℃ temperature and 90%+/-3% humidity

Hysteresgraph:

Mainly test the magnetic characteristics of the magnet, including Residual (Br ), Coercive(Hcb) . Intrinsic Coercive(Hcj), Max. Energy product(BH max) and any other related magnetic parameters.

HSMAG Magnets has been supplying high quality Neodymium Magnets to customers for about 20 years.

Super Magnet

Made of neodymium, the most powerful magnet material in the world

Great for projects that require extreme strength in a small size

Permanent magnetism guaranteed

Not for children