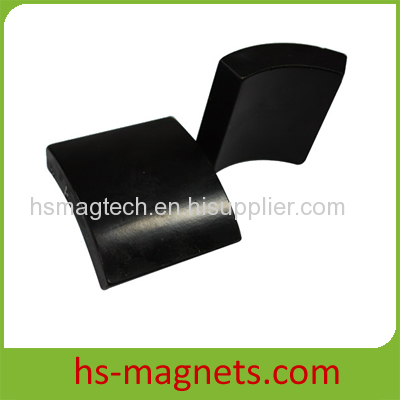

Sintered Motor Permanent Arc Magnets Black Epoxy

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, PAYPAL, T/T, WU |

| Supply Ability: | 1000000000 PCS |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Magnet, Permanent Magnet, Sphere Magnet |

Product Detail

| Model No.: | ARC-20 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Shape: | Arc |

| Application: | Motor Magnet |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | HSMAG |

| Material: | Sintered Neodymium-Iron-Boron |

| Size: | according to customers' request |

| Application: | sensors,motors, rotors,wind turbines,wind generators |

| Coating: | Black Epoxy / Ni-Cu-Ni |

| Certificate: | ISO9001:2008, SGS test report |

| Production Capacity: | 1000000000 PCS |

| Packing: | High quality cartons or according to customers' requirements |

| Delivery Date: | 7-15 days |

Product Description

Neodymium magnets (NEO)

1)Shape: Block,Ring,Disc,Arc,Sphere etc

2)Grade:N35-N52,N35M-N48H etc

3)Certificate:ISO9001:2008;ROSH

Neodymium magnets (XINFENG MAGNET Brands)

1. Specification of Neodymium Magnets:

Chemical composition: Nd2Fe14B.

Neodymium magnets are hard, brittle and easily corrode.

2. Moderate temperature stability

Neodymium magnets lose -0.09 ~ -0.13% of Br/°C.

Their working stability is under 80°C for low Hci Neodymium magnets and above 200°C for high Hci Neodymium magnets.

3. Excellent strength value

High magnetic performance (Br: 11,000 to 14,500 GS, Hcj: 11,000 to 30,000 Oe, BHmax: 35 to 50 MGOe)

4. Advanced Technology

The choice of Strip casting and HDDR technology in our factory allows us to make high performance Neodymium Magnets of N52 possible. The standard properties, N33, N35, N38, N40, N42, N48, N50, N52 (M, H, SH, EH, UH)

5. Extremely resistance to demagnetization

Advantages:

• Highest magnet strength available

• High resistance to demagnetization

• Operating temperature up to 240ºC

• Good at withstanding low temperatures (down to – 100ºC)

Corrosion protection is however always recommended for sintered neodymium magnets, because of the materials low corrosion resistance. The corrosion resistance of sintered NdFeB magnets can be compared to pure untreated iron.

A range of different coatings are available but sometimes complete encapsulation in i.e. stainless steel is preferable.