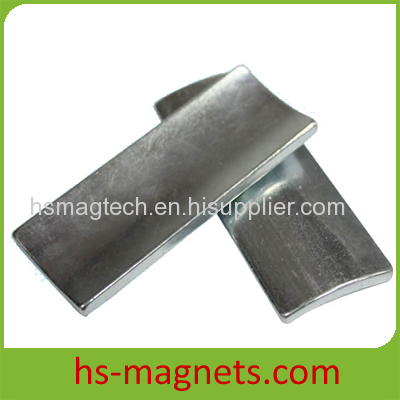

Sintered Motor Permanent Segment Magnets

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, PAYPAL, T/T, WU |

| Supply Ability: | 1000000000 PCS |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Magnet, Permanent Magnet, Sphere Magnet |

Product Detail

| Model No.: | ARC-19 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Shape: | Arc |

| Application: | Motor Magnet |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | HSMAG |

| Material: | Sintered Neodymium-Iron-Boron |

| Size: | according to customers' request |

| Coating: | Ni-Cu-Ni |

| Application: | sensors,motors, rotors,wind turbines,wind generators |

| Certificate: | ISO9001:2008, SGS test report |

| Production Capacity: | 1000000000 PCS |

| Packing: | High quality cartons or according to customers' requirements |

| Delivery Date: | 7-15 days |

Product Description

HSMAG offers neodymium magnets in square and rectangular blocks. These neodymium iron boron magnets are widely used for motor, sensor and holding applications.

Features include:

• Neodymium magnets are the most powerful commercially produced magnets.

• Neodymium magnets are hard and brittle and may chip or break if dropped.

• HSMAG Neodymium magnets are magnetized through the thickness.

• Uncoated neodymium magnets may corrode in humid conditions.

• Operating temperatures vary among material grades. For a comparison of neodymium material grades, please visit our chart of material properties.

• Neodymium magnets are often assembled into products using strong adhesives such as Loctite 325. Make sure that all contact surfaces are clean and dry prior to bonding.

• Please use caution when handling magnetized neodymium magnets, their exceptional magnetic force may cause them to attract to metal (or to each other) so strongly that fingers in their path could prove painful.

Advantages:

• Highest magnet strength available

• High resistance to demagnetization

• Operating temperature up to 240ºC

• Good at withstanding low temperatures (down to – 100ºC)

Corrosion protection is however always recommended for sintered neodymium magnets, because of the materials low corrosion resistance. The corrosion resistance of sintered NdFeB magnets can be compared to pure untreated iron.

A range of different coatings are available but sometimes complete encapsulation in i.e. stainless steel is preferable.