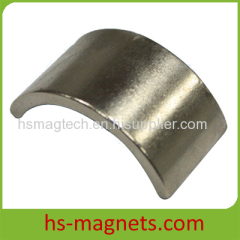

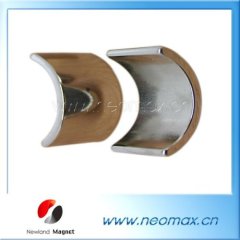

Motor Neodymium Segment Magnets

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, PAYPAL, T/T, WU |

| Supply Ability: | 1000000000 PCS |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Magnet, Permanent Magnet, Sphere Magnet |

Product Detail

| Model No.: | ARC-11 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Shape: | Arc |

| Application: | Motor Magnet |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Brand Name: | HSMAG |

| Material: | Sintered Neodymium-Iron-Boron |

| Size: | according to customers' request |

| Coating: | Ni-Cu-Ni |

| Application: | sensors,motors, rotors,wind turbines,wind generators |

| Certificate: | ISO9001:2008, SGS test report |

| Production Capacity: | 1000000000 PCS |

| Packing: | High quality cartons or according to customers' requirements |

| Delivery Date: | 7-15 days |

Product Description

Motor magnets and Rotor magnets are most in Arc or segment shape.some are Block magnets .

Arc Magnets is one special shape of Rare earth magnets and perment magnets.

It is always manufactured via Wire Cutting and grinding etc .Regular Arc magnets or Segment magnets have the following important factors such as ,Outer Diameter Or Outer Radius,Inner Diameter or Inner Radius ,Degree of Angle,Thickness,Length ,Round Edge etc.

Generally speaking,Arc Magnets are all made as Customer Design and as Special requirement.

Our factory produce and manufacture magnets according to customer's design on shape, dimension, grades, coatings etc.

To offer you our Arc magnets price,please offer the following details :

Magnets grade :from N35 To N50 ,from N Series to UH Series.

Magnets drawing with size and shape and different side view .

Magnetism direction :Mostly magnetized via diameter ,if special magnetism direction,please show on the drawing in advance.

Magnets coating :Nickel ,Zn,Black Epoxy,Ag,Au Etc.

Quantities: More mass order quantities. More Lower the prices. Original factory .

Permanent Magnets - Applications

For special applications, e.g. in the event of direct contact with water, it may be necessary to apply a surface treatment to certain types of magnets.

We provide different options for surface treatment such as nickel, zinc and epoxy, or alternatively complete enclosure in stainless steel.

The potential applications for magnets are endless, but the most common include:

Motors

Couplings

Sensors

Holding systems

Loudspeakers and microphones

We ourselves use permanent magnets for our magnetic systems, couplings, rotors and other magnetic subcomponents.

.jpg)