Automatic Door Seal Production Line

| Min. Order: | 5 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

| Main Products: | Door Seal Production Line |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Plastic Type: | PVC |

| Brand Name: | JG |

| Power: | 35KW |

| Capacity: | 8-20 m/min |

| Shift production: | 5000-7000 m |

| Entire line length: | 26 meters |

| Production Capacity: | 20sets/month |

| Packing: | Buyers investment |

| Delivery Date: | 1 month |

Product Description

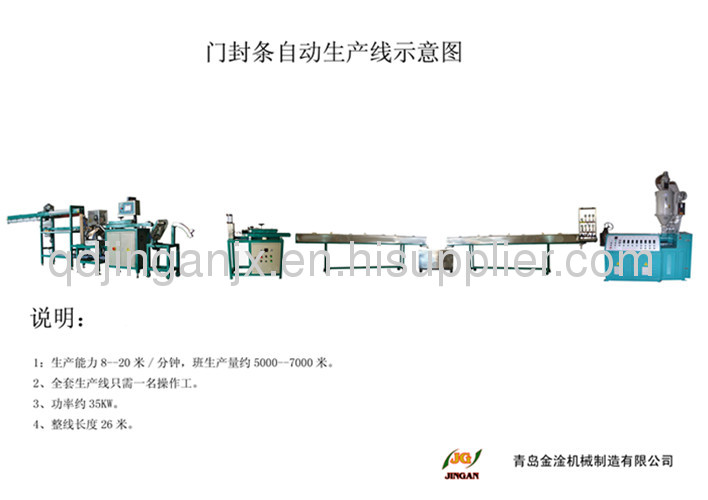

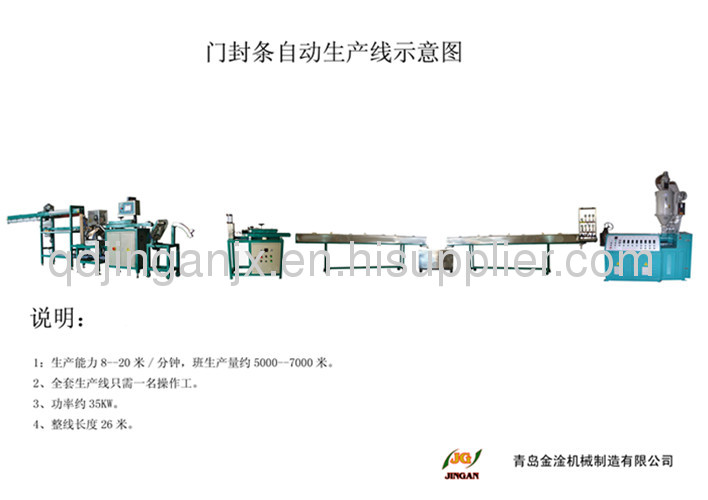

Automatic production line for door seals

Production capacity of 8-20 m/min,and shift production of about 5000-7000 m.

The full line of only one operator.

Power of about 35KW.

The entire line length 26 meters.

Technical information

Overview:this production line is fully automated production line,PVC modified mixed with not more than 25 percent of the crushed material by artificial feeding to Banliao-automatic dry feeding machine-extruder hopper by the extruder plasticizing extrusionthrough the extrusion die stereotypes-stereo-types die cooling and sizing-and into the circulating water cooling-compressed air to blow water - automatic traction cutting machine,traction cut off-automatic punch by playing empty and was empty mold - traction conveyor - angle cutter for precise cutting angle of 45°- the robot automatically reclaimer - Artificial finished door seal plate removed.

1.The main features of the production line automation of production ,high production efficiency.Completed the punch while the production of door seals,and 45°precision cutting Cutaway,the robot automatically take materials such as process,the entire line just one or two operation ,each removal of the material angle is 1/5 of the old production lines,large the margin improved yield.Electrical control PLC of OMRON corporation,controlled by touch screen,the entire line between the various processes to configure a smart program,parameter setting operation through the touch screen,you can get qualified products.

2.The main technical parameters

(1)production line length 26M

(2)the center of the extruder 1050MM

(3)Total power.about 50KW

(2)the center of the extruder 1050MM

(3)Total power.about 50KW

(4)The production capacity of 8-20M/MIN

(5)Voltage:380V50HZ

(6)Source of compressed air:0.5~0.6MPA

3.Configuration technical note

(1)extruder section

The extruders host configuration table

Reducer:origin Jiangsu jiangyin Kewei the model 2LY200 hardened material 38CROMAL,carburizing touch tooth treatment,Maximum power 50KW,speed ratio of 28:a roughness of 0.08.

Main Drive Motor:18.5KW AC motor.

Cooling parts:the barrel with five automatic air-cooled fan,the cutting area with water cooling,fan power is 160W/.

Heating parts:the body using electric heating of the five districts,each districts,each district power 2KW,nose,3KW,heating power 30KW.

Part of temperature control:thermometer Chint(national best).

Manually changer.

(2)Spray parts:double stainless steel sink(two 4M)

(3)Door seals and automatic traction cutting machine

Frequency Control,timing belt,the upper and lower screw adjustment,automatic traction cut off,

(4)Drilling machine

Punched in the door gasket production line unit automatically punch the door seals,to facilitate the welding of the back door seal box exhaust to maintain good flexibility.

(5)Traction conveyor

OMRON servo motor,belt drive,the upper and lower pressure can be adjusted,photoelectric and fiber,and the encoder control.

(6)Notching Machines

Automatically according to the size of the set to the door seals both ends of the 45°cutting angle cutting.Notching cutting precision ±1MM

(7)Automatic reclaimer

Automatic cutting profiles by the manipulator automatically the reclaimer placed in the box placed on the feeder.

Automatic Door Seal Production Line

Automatic Door Seal Production Line