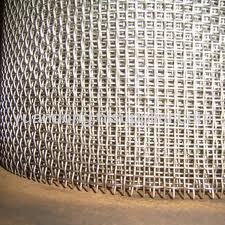

Crimped wire mesh

369.0~669.0 USD

| Min. Order: | 150 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Place of Origin: | Hebei |

Company Profile

| Location: | Beijing, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Wire Mesh |

Product Detail

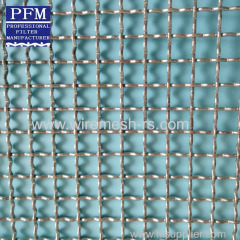

| Model No.: | Ametal-2 |

|---|---|

| Means of Transport: | Ocean, Air |

| Application: | Sieving Diversified Pellet |

| Type: | Woven |

| Material: | Others |

| Brand Name: | Ametalmesh |

| Mesh Size: | 1.8mx40m |

| Packing: | film plastic |

| Delivery Date: | 14days |

Product Description

Crimped wire mesh

Material: Iron wire.

Weaving Pattern: Weaving after crimping

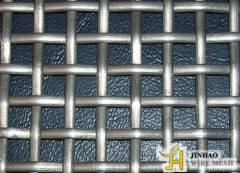

General Use: Crimped wire mesh is used in screening in mine, coal factory, construction and other industries. Some galvanized crimped wire mesh and stainless steel crimped wire mesh are for roasting of flour food and meat.

General Use: Crimped wire mesh is used in screening in mine, coal factory, construction and other industries. Some galvanized crimped wire mesh and stainless steel crimped wire mesh are for roasting of flour food and meat.

Specification :plane sieve plate, curving sieving mesh

Capability: solid , durable, press-resist

Manganese steel mine sieving mesh adopt inserting style to weave the mesh .the fold part of longitude and latitude won't extrude so the surface is smooth.the hardness is HB180-230.it has good character of molding and toughness.when it is suffering fierce strike and attrition ,the surface is changed .the hardness of the surface can go up to HRC60.so it has good wearability .inner side still have finer molding and toughness ..it will form a new layer of wearability when the old surface is distoryed . Therefore the life of the weaved mine sieving mesh can be achieved in 4-6 times than the ordinary mine sieving mesh.

Usage

There is a suit of machine to product the Manganese steel mine sieving mesh such as :the machine of shaky sieving mesh, roller sieving mesh machine ,high frequency electromagnetism sieving machine and asphaltum mixed machine.

There is a suit of machine to product the Manganese steel mine sieving mesh such as :the machine of shaky sieving mesh, roller sieving mesh machine ,high frequency electromagnetism sieving machine and asphaltum mixed machine.

Specification List of Crimped Wire Mesh:

|

.jpg)