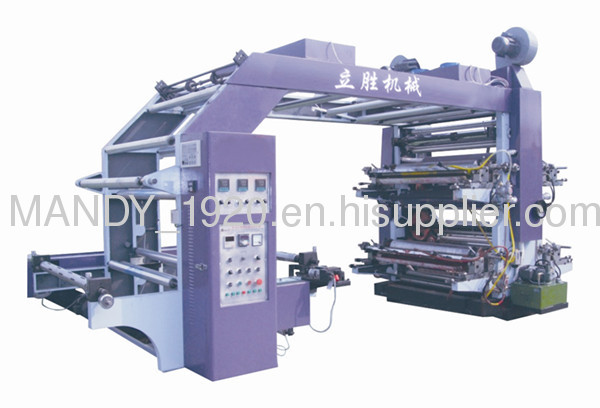

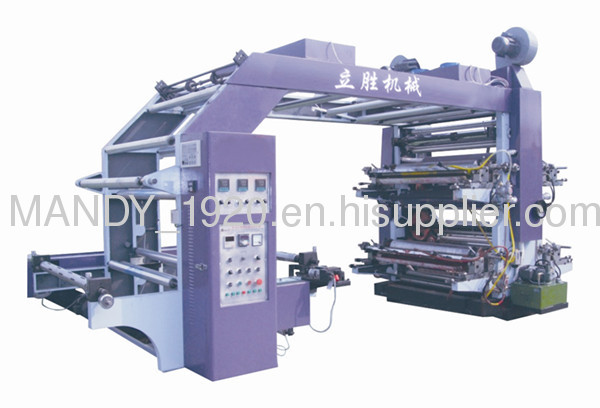

LS-series four-color high speed flexographic printing machine

18000.0~20000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 15set |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wenzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Printing Machine Blowing Machine Bag Making Machine |

Product Detail

| Model No.: | LS-600/800/1000/1200 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | lisheng |

| Production Capacity: | 15set |

| Packing: | unde packing |

| Delivery Date: | 30days after deposit |

Product Description

LS-Series four-color high speed flexograpic printing maching

performance

1,reasonable structure ,advanced technology,easy operation ,atable performance ,accurate color regster

adopting high-quality motor,high-quality inverter ,save the electricity,reducethe run fluctuation

3.when the machine is stopped working ,printing rolls still keep moving;when rise the printing roller,ink motor running automatically ;when fallen the printing roller,ink motor stop running automatically

4the machine is equipped with bloer and heatr ;and the heater employed central temperature control system

5the use of individual drying oven and cold wind system,can effectively prevent the ink adheasion after printing

6.roller adopts special steel processing,and through special treatment,greatly reduce the beating range

7printing roller use static balance and dynamic balance processing,hard anode oxidation treatment,small resistance,beating small achieves finally perfect printing effect

8accurate printing effect achieved by special gear transmission device

9the printing machine all can choose advanced configuration to achieve the high quality,the high-defination printing effect

main technical variables

performance

1,reasonable structure ,advanced technology,easy operation ,atable performance ,accurate color regster

adopting high-quality motor,high-quality inverter ,save the electricity,reducethe run fluctuation

3.when the machine is stopped working ,printing rolls still keep moving;when rise the printing roller,ink motor running automatically ;when fallen the printing roller,ink motor stop running automatically

4the machine is equipped with bloer and heatr ;and the heater employed central temperature control system

5the use of individual drying oven and cold wind system,can effectively prevent the ink adheasion after printing

6.roller adopts special steel processing,and through special treatment,greatly reduce the beating range

7printing roller use static balance and dynamic balance processing,hard anode oxidation treatment,small resistance,beating small achieves finally perfect printing effect

8accurate printing effect achieved by special gear transmission device

9the printing machine all can choose advanced configuration to achieve the high quality,the high-defination printing effect

main technical variables

| model | 600 | 800 | 1000 | 1200 |

| printing color | four color | |||

| printing width | 600mm | 800mm | 1000mm | 1200mm |

| printing length | 190.5-1016mm | |||

| printing plate lifting system | manual/automatic | |||

| machine apeed | 3-100m/min | |||

| printing speed | 3-80m/min | |||

| anxilox cylinder | 50-1000LPI | |||

| register precision | ±0.15-±0.24 | |||

| rewinder/unwinder DLA | ±600MM | |||

| main motor | 1.5kw | 2.2kw | 4kw | 4kw |

| total power | 20kw | 22kw | 27kw | 30kw |

| weight | 4400kg | 4800kg | 5000kg | 5200kg |

| dimension | 5.5 ×1.65 ×2.4m | 5.5× 1.8 ×2.4m | 5.5 ×2.0 ×2.4m | 5.5× 2.2 ×2.4m |