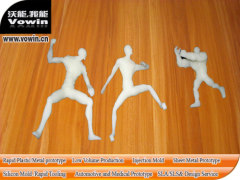

Rapid prototype

1.0~1000.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 100 pcs/day |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Zhongshan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

| Main Products: | Rapid Prototyping, Injection Mold, Plastic Injection |

Product Detail

| Means of Transport: | Air |

|---|---|

| Product: | Household Appliance |

| Product Material: | Plastic |

| Shaping Mode: | Preform Mould |

| Brand Name: | Hansun |

| Production Capacity: | 100 pcs/day |

| Packing: | carton |

| Delivery Date: | 3 days |

Product Description

With more than 10 years of rich and professional Rapid Prototyping experience, and advanced laser rapid prototyping equipment from US and Germany (SLA laser Stereo lithography and SLS Laser Sintering), Hansun is able to manufacture CNC prototypes, laser prototypes and complex structure accessories model or non-standard high-end product model. Both in quality and technology, we can guarantee customer a satisfactory solution.

CNC-CAD/CAM,.,,.,,.

SLA-(Stereo lithography),.,(),.,,,,.,,,\.

SLS-(Slected laser sintering),().,.,,,,,.,,,.

SLS (Selected Laser Sintering): Carbon dioxide laser selectively sinter the raw material--powder material (Mixture with plastic powder and binder). Working principle: computer controlled laser beam sinters the powder material in accordance with the cross-sectional profile, then the powder melting and then a layer of solid contours is formed. The workbench moves down a layer distance and covers a new layer. Keep repeating until the entire 3D prototype is finished. Advantage: low rate of water absorption, aging resistance and chemical resistance for functional parts.

-(Silicone Mold)CNCSLA,,8.,.,,.

Silicon Mold: Firstly, make original mold from CNC or SLA, and put the original mold into the silicone fluid. 8 hours later, the silicone mold has been solidified. Secondly, put the liquid gum material into the silicone mold so that the same prototype part can be made. Advantage: short lead time, low cost and short production cycle for small amount production.

-,(20-25),,,5000-10000.

1. CNC:ABS PP PMMA PC POM PTFE PPSGF40 PBT PE

2. SLA:DSM14120

3. SLS:PA2200+GF,PA3200+GF

4. :8150,8090,8400,PX521,8550,4280,6160,PX223HT

1. CNC: ABS, PP, PMMA, PC, POM, PTFE, PPSGF40, PBT, PE

2. SLA: DSM14120

3. SLS: PA2200+GF, PA3200+GF

4. Silicone Mold: 8150, 8090, 8400, PX521, 8550, 4280, 6160, PX223HT