Gas Pipe PE-AL-PE Pipe Making Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100sets per year |

| Place of Origin: | Shandong |

Company Profile

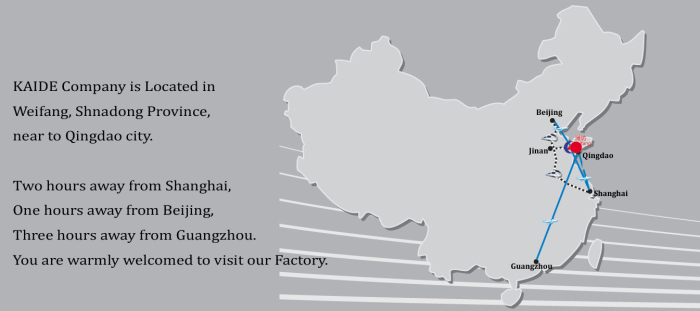

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | KAIDE |

| Power: | 65kKW |

| NAME: | pex al pex pipe machine |

| Pipe diameter: | 16mm-32mm,16mm-63mm |

| Line speed: | 3-8m/min |

| Inverter controller brand: | ABB Brand |

| Control System: | Siemens PLC System |

| Electrics: | Schneider |

| Production Capacity: | 100sets per year |

| Packing: | Polyfim |

| Delivery Date: | 60 days |

Product Description

High Efficient Extruder

This high efficient extruder of this PE-AL-PE pipe line is specially independently designed by KAIDE company.It includes:

Inner PE Layer Extruder,

Inner Glue Layer Extuer,

Outer PE Layer Extruder,

Outer Glue Layer Extruder

Ultrasonic Welding Machine

The Aluminum tube was sealed by ultrasonic welding, which adopts high well-known brand welder, with even and strong welding seam.

Aluminum pipe forming moulds

The technology has been further developed based on original production machine technology.

The Aluminum pipe forming molds and co-extrusion die head molds have been optimized and manufactured by imported high precise CNC machine, which have greatly increased the pipe forming accuracy and production speed.

PLC control system

The PE-AL-PE Pipe Extrusion Line adopts original Siemens new generation PLC control system with full color screen, which ensures the high speed synchronous control and reliable operating of the whole production line.

Manufactured PE-AL-PE Gas Pipe

The PE AL PE GAS PIPES is a product that imposing very quickly and in very short time. It will be the material with more participation in the construction of Gas systems.

The reasons lies in:

The reasons lies in:

The acceptance by the Gas Distribution Companies

As material, PE-AL-PE PIPES is much more economical than copper, and it is almost the same cost of galvanized steel pipes;

Much easier to install, whole system will take 1-2 hours to complete, no need of heavy tools, installation workers can learn fast and save energy;

The flexibility of the pipe has the advantage of NO fittings needed in every change of directions, avoid possibility of gas leaking & save cost.

The minimun life time is 50 years.