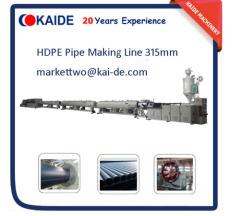

High Speed 20m-63mm HDPE Pipe Making Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, L/C, T/T, WU, Money Gram |

| Supply Ability: | 100sets per year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | KAIDE-HDPE |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | KAIDE |

| Power: | 75KW |

| Name: | HDPE Pipe Making Machine |

| Diameter: | 20mm-63mm,20mm-110mm |

| Line speed: | 15m/min,30m/min,50m/min |

| Extruder: | SJ65,SJ60,SJ75 |

| Control system: | PLC |

| Inverter Brand: | ABB |

| Electrics: | Schneider |

| keyword: | HDPE pipe production machine |

| Package: | Soft film packing |

| Oversea Service: | Engineer is available for overseas service |

| Production Capacity: | 100sets per year |

| Packing: | Soft package for sea transportation |

| Delivery Date: | 60 days |

Product Description

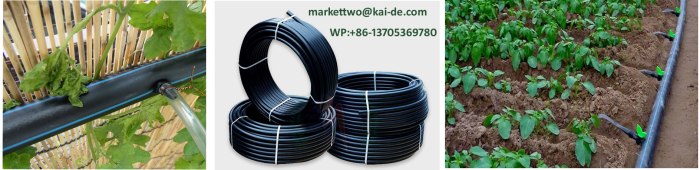

High Speed HDPE Pipe Production Line

High speed HDPE pipe line adopts specially designed high efficient five-section type screw and barrel, which are our company independent design, with completely independent intellectual property rights.

| Line Model | Screw Diameter | L/D | Production Speed | Nominal Power |

| SJ-75 | Ф75mm | 36:1 | 50m/min | 155KW |

| SJ-60 | Ф60mm | 36:1 | 35m/min | 104KW |

| SJ-80 | Ф80mm | 33:1 | 25m/min | 112KW |

| SJ-65 | Ф65mm | 33:1 | 15m/min | 76KW |

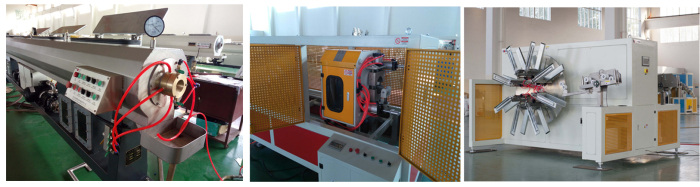

Die head

(1)The specially designed spiral pressure-storage die head of this HDPE pipe making machine effectively overcomes the instantaneous fluctuation of extrusion pressure,

(2)Realizing high speed and constant pressure extrusion of materials.

Siemens PLC control system

(1)The production line to make PERT pipe adopts original new generation PLC control system.

(2) Adopting Multi-point closed loop control system, ensuring high speed synchronous control and reliable operating.

Other Functions

Added some auxiliary machine, the HDPE pipe production line can be used as PPR Pipe Making Machine, PERT Pipe Making Machine, 3 Layers PERT/EVOH Pipe Machine