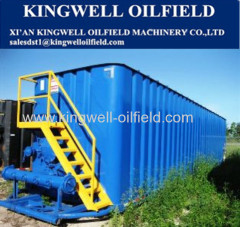

Drilling Fluid Storage Equiment Mud Tank

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 SETS/MONTH |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | FG |

|---|---|

| Means of Transport: | Ocean |

| type: | mud tank |

| Production Capacity: | 20 SETS/MONTH |

| Packing: | wooden package for transport as per the equipment size |

| Delivery Date: | 25 days after receiving 30% deposit |

Product Description

Drilling mud tank is an indispensable part of mud circulation system and it can complete the weighting,mixing, solid-liquid separating,degassing and other processes. The drilling mud tank carries the mud circulating between the well head and mud pumps. The solid phase particles in mud are separated stage by stage by relevant solid control equipments on the driling mud tank and they are mixed by mud weighting and mixing system to meet the requirements of drilling process. The degasser on the driling mud tank can remove the harmful gas in the mud to ensure the environmental requirements of working site and the mud specific gravity. The mud tank applies centralized control of electric. Heating system and heat preservation system are installed for polar regions. The drilling site usage of mud tank has the following advantages: ensuring no mud loss, reducing environmental pollution, lowering labor intensity and meeting the requirements of the drilling process timely by mud mixing. Tanks can be designed and manufactured according to the specific requirements of our customers.

Type FG drilling fluid mud tank designed and manufactured by our company is devided into Square tank and Cone-shaped tank according to the shape of tank bottom. The body of the drilling fluid mud tank is made of welding the steel plate and section, using the flat cone-shape structure or the corrugated structure. The mud tank surface and the passage are made of the slipping resistant steel plate and linearity netted steel plate which is produced by the professional factory, the mud tanks are made of the side steel pipe, all of the structure can be folded without barrier and pegged reliably. The surface of tank is equipped with water pipeline for cleaning the surface and equipment on the mud tank, we use soaked zinc processing for the netted steel plate. The ladder is made of the channel steel to take responsibility the body, the foot board is made of the linearity netted steel plate. The two-sided guard rail are installed the safe suspension hook. The mud tank is designed the standard shanty to prevent the sand and the rain. The pipeline is installed in the tank to preserve the warm air heat.

Besides mud tank ,can also design and provide water tank ,fuel tank,mixing tank,storage tank.

When inquiry pls specific your mud tank requirements ,such as the treating capacity and the mud tank length information.

As a mud carrier, mud tank is an indispensable part of mud circulation system and it can complete the weighting,mixing, solid-liquid separating,degassing and other processes. The mud tank carries the mud circulating between the well head and mud pumps. The solid-phase particles in mud are separated stage by stage by relevant solid control equipments on the mud tank and they are mixed by mud weighting and mixing system to meet the requirements of drilling process. The degasser on the mud tank can remove the harmful gas in the mud to ensure the environmental requirements of working site and the mud specific gravity. The driling mud tank applies centralized control of electric. Heating system and heat preservation system are installed for polar regions.

Contact Information:

Email: julinliang at trsolidcontrol.cn

Msn : tr.solid.control at msn.cn

Mobile phone: 8615229262604