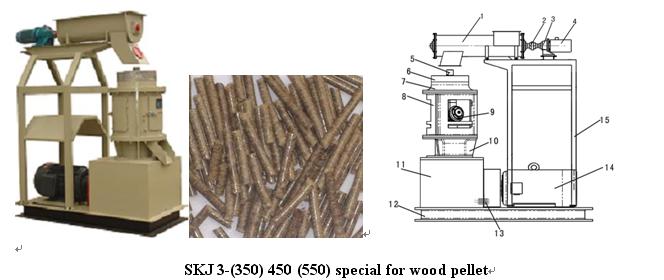

HRWR Series Wood Pellet Mill

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Pellet Mill Flat Die Pellet Mill Ring Die Pellet Mill Feed Pellet Mill Wood Pell Mill Crushing Machine |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| high quality: | low price |

Product Description

Features and Advantages

1.Low noise, energy saving and high output with continuous production.

2.The machine reliability and service life can be improved by adopting oil cooling lubricating system, which automatically lubricates each main bearing and oil seal.

3.The advanced gear driving device is made of wear-resisting material and forged by vacuum furnace heating treatment making the operation stable and capacity is 15% higher than belt driving.

4.Adopt SKF bearing and NAK oil seal with more than 30000 hours gear service life.

5.As the biomass sawdust is of light weight, so they are needed to be pushed into pelletizing chamber by force to ensure the pelletizing process in a continuous and smooth way.

6.It adopts imperative feeding device.

Ring Die Pellet Mill Working Principle

After the material is sent into feeder, the screw conditioner will mix them evenly and then distributes the sawdust to pelletizing chamber. The rollers in the chamber drive the material into holes of ring die to form pellets. Meanwhile, there are several knives to cut the pellets into different size as they need. At last, the pellets will be discharged into a container ready for use.

HRWR Series Wood Pellet Mill Technology Data

Model | Power(kw) | Capacity | Dimension |

HRWR 320 | 37kw | 0.3~0.5t/h | 2100*800*1300mm |

HRWR 350 | 55kw | 0.4~0.6t/h | 2200*900*1500mm |

HRWR 400 | 75kw | 0.8~1t/h | 2300*1000*2100mm |

HRWR 420 | 90kw | 1~1.2t/h | 2300*1000*2100mm |

HRWR 508 | 132kw | 1.5~2.2t/h | 3200*1300*1900mm |

HRWR 558 | 160kw | 2.5~3.5t/h | 3500*1500*2800mm |

Wood Pellets Size: 6mm, 8mm,9mm,10mm ,12mm

Quality Guarantee: 2 years guarantee for main body.

.jpg)

.jpg)