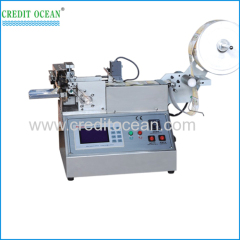

Automatic Cross Cutting Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, D/A, T/T |

| Supply Ability: | 1000Set/ Sets per Month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Cut To Length Machine |

Product Detail

| Model No.: | JN4004 |

|---|---|

| Means of Transport: | Ocean |

| Power: | Cnc |

| Machine Type: | Beading Machine |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | KENUO |

| Condition: | New |

| Horizontal Shear: | Horizontal |

| Production Capacity: | 1000Set/ Sets per Month |

| Packing: | According to customer's request |

| Delivery Date: | 20 days after prepayment done |

Product Description

Automatic Cross Cutting Machine

It is our company's newly developed machine which meet the customer's special requirements ----- There are three cradles which means put three roll materials,and the dia of unwinding of each unwinder is flexible.The advantage is that can improve capacity for enterprise.

It is our company's newly developed machine which meet the customer's special requirements ----- There are three cradles which means put three roll materials,and the dia of unwinding of each unwinder is flexible.The advantage is that can improve capacity for enterprise.

Usage:

This machine is suitable for cutting big rolling packaging materials such as paper, paper-plastic, multicolor laminated material ,etc.

This machine is suitable for cutting big rolling packaging materials such as paper, paper-plastic, multicolor laminated material ,etc.

Performance and Characteristics:

It adopts servo motor for controlling constant-length cutting.

It adopts pneumatic,displacement sensor for controlling transmission system, with photoelectric, gas together,1 it has the function of easy operation, high precision, good stability, low noise.

Automatic Cross Cutting Machine

This machine has the function of the frequency converter timing device, automatic counting, stop working by alarm which tell you the machine reach a certain number of sheets cut ,magnetic powder tension control

JN4004-type horizontal shear machine

cutting width: 50-400mm,

cutting length: 1-999999mm,

length accuracy: ± 0.1mm,

shear thickness: 0.23-0.6mm,

shear burr ≤ 0.03mm.

The price: 470, 000 Yuan.

cutting width: 50-400mm,

cutting length: 1-999999mm,

length accuracy: ± 0.1mm,

shear thickness: 0.23-0.6mm,

shear burr ≤ 0.03mm.

The price: 470, 000 Yuan.

This machine has the function of the frequency converter timing device, automatic counting, stop working by alarm which tell you the machine reach a certain number of sheets cut ,magnetic powder tension control

It can be cut vertically ,adopt blower fan to get rid of waste.It controlled by microcomputer.

Abrasive systems: The machine adopts precision die abrasive, to ensure the accuracy requirements of the mold. Mold selected high hardness of alloy ceramic steel imported from Germany, the number of grinding stamping more than 5 million times, you can freely adjust the shear rate, shear depth.

Horizontal shear machine are used for the metal steel coil unwinding, school level, cut to length, cut into the flat sheet of required length and stacking. Applicable to the processing of cold-rolled and hot rolled carbon steel, silicon steel, tinplate, stainless steel and various types of metal materials in surface coating.

We also undertake designing, processing and installing of various mechanical equipments, including electric furnace, continuous casting machine and rolling mill; manufacturing and fabricating the welding, casting and forging parts with various specifications etc. We are also engaged in heating treatment, surface treatment of various metals, steel structure design, manufacture and installation of various plant buildings for plants and mines.

The tenet of our company is "Credit First, Quality First and Service First". New and regular friends from anywhere at home and aboard are welcomed to establish friendly cooperation partner relationship with our company on long-term basis.