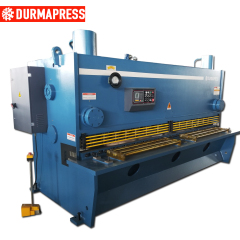

Good Performance Hydraulic Shearing Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, D/A, T/T |

| Supply Ability: | 1000Set/ Sets per Month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Cut To Length Machine |

Product Detail

| Model No.: | JN2003 |

|---|---|

| Means of Transport: | Ocean |

| Power: | Cnc |

| Machine Type: | Beading Machine |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | KENUO |

| Condition: | New |

| Horizontal Shear: | Horizontal |

| Production Capacity: | 1000Set/ Sets per Month |

| Packing: | According to customer's request |

| Delivery Date: | 20 days after prepayment done |

Product Description

Good Performance Hydraulic Shearing Machine

Good Performance Hydraulic Shearing Machine

Descriptions:

All welded structure, vibrating treatment of ageing for removal of internal stress for Hydraulic Shear with good rigidity stability Integrated hydraulic transmission system, with good reliability for Hydraulic Shear

Good Performance Hydraulic Shearing Machine

Descriptions:

All welded structure, vibrating treatment of ageing for removal of internal stress for Hydraulic Shear with good rigidity stability Integrated hydraulic transmission system, with good reliability for Hydraulic Shear

Triple support rolling guide rail to eliminate gaps of support and enhance shearing quality for Hydraulic

ShearBack gauge use intelligent digital display device, shear quantity can be automatic counted for Hydraulic Shear distance of back gauge can be set according to requirements of customers for Hydraulic Shear.

Clearance between shearing blades adjusted by hand wheel to be quick, accurate and convenient for

ShearBack gauge use intelligent digital display device, shear quantity can be automatic counted for Hydraulic Shear distance of back gauge can be set according to requirements of customers for Hydraulic Shear.

Clearance between shearing blades adjusted by hand wheel to be quick, accurate and convenient for

Rectangular blades with four cutting edges to prolong working life, adjustable shearing angle to reduce

deformation of the sheet Upper blade holder has inward tilting structure to facilitate material feed in and

also enhance accuracy of the work piece Function of shearing in sections, function of lamplight illume deviceOptional rear material holding device Metal Plate Cutting Machine Metal Plate Shearing Machine

Feed system: Scroll wheel used high hardness abrasive steel, Roller Bearing are refined from CNC cutting.

Computer IPC: Delta Pic host points 40, 16k memory, 30 kHz high-speed counting, DVP20EHOOT2.

Touch screen: 5.7 high brightness of display, multicolor, operation via a touch can easily complete the number of pieces, length, speed, numbers of punching, and holes center distance parameters corrective action.

Feed system: Scroll wheel used high hardness abrasive steel, Roller Bearing are refined from CNC cutting.

Abrasive systems: The machine adopts precision die abrasive, to ensure the accuracy requirements of the mold. Mold selected high hardness of alloy ceramic steel imported from Germany, the number of grinding stamping more than 5 million times, you can freely adjust the shear rate, shear depth.Punching system: Self-developed high-speed stamping system.