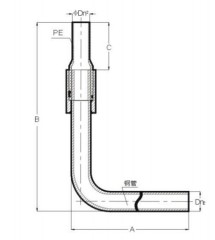

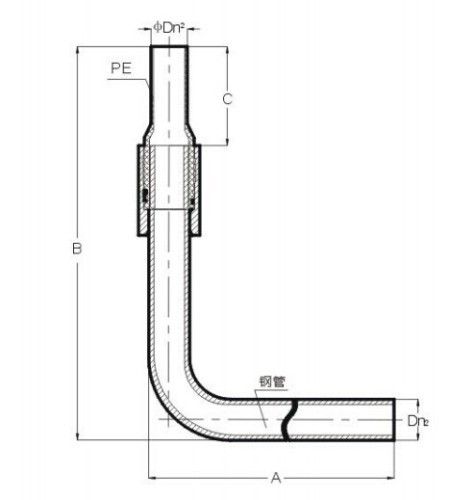

PE-Steel Adapter With 90 Degree Pipe Fitting

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100000/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | XM-PSA003 |

|---|---|

| Means of Transport: | Ocean, Air |

| Head Code: | Others |

| Shape: | Reducing |

| Technics: | Others |

| Type: | Elbow |

| Material: | Carbon Steel |

| Connection: | Welding |

| Brand Name: | OEM |

| Material: | HDPE and Steel |

| Working Pressure: | SDR11 |

| Working Tempreture: | -40℃~40℃ |

| Connection: | Welding |

| Specifications: | DN25x27~DN63x60 |

| Working Medium: | Gas |

| Color: | Black |

| Working Life: | More than 50 years |

| Packing: | Cartons or Bags |

| Export Area: | All over the world |

| Production Capacity: | 100000/month |

| Packing: | carton |

| Delivery Date: | 45 days |

Product Description

PE-Steel Adapter With 90 Degree Pipe Fitting

PE-Steel adapter: Connecting PE pipes and pipe fittings.

Anticorrosive epoxy coating using a coating of 400u above, do not need to use anti-corrosion treatment when you use the pe-steel adapter.

***Product features:

Entirety formed pipe fittings; it can be connected with polyethylene pipeline by using electro heating fusion casing or heat-fusion butt jointed.The seamless steel pipe connected polyethylene end firmly,adopted the end seal technique,wihi anti-shift measures and reinforcing sleeve guard.

**Specifications of pe-steel adapter with 90 degree pipe fittings

| |||||

| Size | Out Diameter of PE Pipe (ΦD1) | Out Diameter of Steel Pipe (ΦD2) | A(mm) | B(mm) | C(mm) |

| Dn25x27 | 25mm | 27mm | 740mm | 410mm | 80mm |

| Dn32x34 | 32mm | 34mm | 740mm | 410mm | 80mm |

| Dn40x34 | 40mm | 34mm | 740mm | 410mm | 80mm |

| Dn40x42 | 40mm | 42mm | 740mm | 410mm | 80mm |

| Dn50x48 | 50mm | 48mm | 740mm | 410mm | 80mm |

| Dn63x48 | 63mm | 48mm | 740mm | 430mm | 80mm |

| Dn63x57 | 63mm | 57mm | 740mm | 430mm | 80mm |

| Dn63x60 | 63mm | 60mm | 740mm | 430mm | 80mm |

***Basic performance of raw materials for pipe fittings

| Paramenter | Units | Requirement | Test Value |

| Density | kg/m³ | ≥930 | 23ºC |

| Melt flow rate | g/10min | 0.2~1.4 | 190ºC,5kg |

| Thermal slaility (OIT) | min | >20 | 200ºC |

| Volati lematter content | mg/kg | ≤350 | |

| Moisture content | mg/kg | ≤300 | ASTM D 4019:1994a |

| Carbon black content | % | 2.0~2.5 | |

| Crbon black dispersion | grade | ≤3 | |

| Gas proof components | h | ≥20 | 80ºC,2MPa(Hoop stress) |

Resistance to slow crack growth (En>5mm) | h | 165 | 80ºC,0.80MPa(Testing pressure) 80ºC,0.92MPa(Testing pressure) |

***Our workshop and equipments