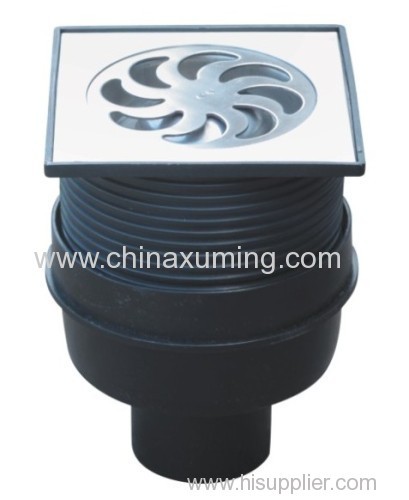

HDPE Made Row Floor Drain Pipe Fittings

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | XM-SD021 |

|---|---|

| Means of Transport: | Ocean, Air |

| Head Code: | Others |

| Shape: | Equal |

| Technics: | Others |

| Type: | Flange |

| Material: | Plastic |

| Connection: | Welding |

| Brand Name: | OEM |

| Material: | HDPE80 or HDPE100 |

| Working Pressure: | SDR26 |

| Working Tempreture: | -40℃~40℃ |

| Connection: | Butt Fusion Injection |

| Specifications: | DN50 |

| Color: | Black |

| Packing: | Cartons |

| Working Life: | More than 50 years |

| Export Area: | All over the world |

| Port of Loading: | Ningbo or Shanghai |

| Production Capacity: | 100000pcs/month |

| Packing: | carton |

| Delivery Date: | 45 days |

Product Description

PE vertical row of floor drain pipe fittings

Floor drain is an important interface to connect the sewer system and the interior surface of housing

as an important component in the drainage system, and its performance directly affects indoor air quality,

the bathroom is very important for odor control.

Floor drain should have four properties: fast drainage, anti-odor, anti-clogging free cleaning.

Floor drain, floor drain, as the name suggests is to drain, floor drain only a single function drain have

been behind the times.

Not only to drain the water fast, the most important thing is to anti-clogging, otherwise too old to clean

up, you no end of trouble up.

The main material to drain

There are cast iron, PVC, aluminum, stainless steel, brass, copper alloys and other materials.

1, cast iron: cheap, easy to rust, unsightly, rusty after hanging sticky dirt, easy to clean;

2, PVC: cheap, easily influenced by temperature deformation, poor scratch resistance and impact

resistance, unsightly;

3, cast: mid-range price, light weight, more rough;

4, stainless steel: affordable, beautiful and durable;

5, copper alloys: affordable, practical.

6, Brass: heavy, high-grade, high prices, surface can be plated.

***Drain - Maintenance

1.Drain pan flavor

Analysis: It may be high enough to drain the water seal, easy to dry, resulting in odor inside

the pan drains into the room.

Solution: First, do not necessarily have to drain the water back bend, plus a go to; Second, for

a same brand, same size floor drain. But construction, careful not to damage the waterproof layer.

In addition, to be reminded that, in use, it should be dry to prevent water seal, subject to regular

water. If long-term leave, preferably with the lid sealed to the floor drain.

2.Drain overflow

Analysis: It may be to drain the cross section is not smooth, sewage can not be quickly passed, or

because of the internal structure of the floor drain punch, tangled up in the hair, fibers and the

like dirt and so on.

Solution: floor drain piping height is determined by the way the drainage system. Therefore, the choice

of ancillary drain height was less than 200mm and preferably less than 120mm, and must lateral drainage. Concealed common practice to local structural floor bathroom sink and toilet piping tube made of two

fabric cushion. In order to meet the requirements of the bathroom clear height and ergonomics, the

former sinking clearance of 300mm, height up to cushion the latter 170mm.

3.Drain water seepage

Workaround: open drain tiles around, surrounded by cement dug 3cm deep, then use the "plugging Ling"

seal about 1 hour closed water test done, to observe whether further seepage, if not seeped it shows restitution.

***Specifications of vertical row of Floor Drain Pipe Fittings

| |

| Size | MOQ |

| Dn50 | 1000pcs |

***Our products has CE certificate