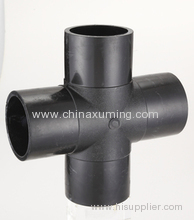

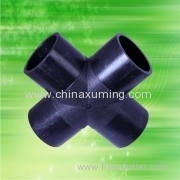

HDPE Butt Fusion Injection Cross Pipe Fittings

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | XM-PEC |

|---|---|

| Means of Transport: | Ocean, Air |

| Head Code: | Square |

| Shape: | Equal |

| Technics: | Others |

| Type: | Elbow |

| Material: | Plastic |

| Connection: | Welding |

| Brand Name: | OEM |

| Material: | HDPE80 or HDPE100 |

| Working Pressure: | SDR17,SDR11 |

| Working Tempreture: | -40℃~40℃ |

| Connection: | Butt Fusion Welding |

| Specifications: | DN90-DN800 |

| Color: | Black |

| Packing: | Bags |

| Working Life: | More than 50 years |

| Export Area: | All over the world |

| Process: | Butt Fusion Welding |

| Production Capacity: | 100000pcs/month |

| Packing: | carton |

| Delivery Date: | 45 days |

Product Description

HDPE Butt Fusion Injection Cross Pipe Fittings

***Advantages and welding of HDPE Butt Fusion Injection Cross Pipe Fittings:

HDPE Butt Fusion Injection Cross Pipe Fittings is light, which is more common for partial application pe80 pe100 grade level and two standards , including :

PE80 density of about 0.94 g / cm 3, PE100 density of about 0.96 g / cm 3 ;

Easy thermoplastic - easy to process ( such as injection molding, extrusion molding

Remanufacturing easy recycling

Good resistance to radiation and chemical stability

Good resistance to cold , the temperature can be -40 ℃ to

Excellent electrical insulation properties , is not affected by electrolytic corrosion

Malleable - extended break PE80> 700% PE100> 600%

Anti- erosion resistance - 8 times better than steel

Approximately half of the low thermal conductivity of glass

Smooth surface , unlike the role of metal pipes rust easily with oxygen crusts

pe pipe connection into fused pipe connections and fittings connected to melt , the more ordinary side, the other , as well as socket connections, this method is applied to a small size.

1 , fused connection : Follow these steps: First check , and then is cut pipe , pipe fittings joints clean , scrape the oxide layer , connecting the two parts of the tube and pipe fittings , calibration welder , welding parameter adjustment in accordance with the welding voltage, welding Dimensions , electricity, welding, and then finally cooled.

2, the hot melt connection : the inner surface of the pipe surface and the pipe is inserted while the welding is non-rotating die head is heated for a few seconds , then quickly removed and welding device , the heat pipe has a fast vertical insertion tube , packing, cooling to .

3 , socket connections, relatively simple, not elaborate here .

***Specifications

| |

| Size | MOQ |

| DN90 | 10PCS |

| DN110 | 10PCS |

| DN160 | 10PCS |

| DN200 | 10PCS |

| DN225 | 10PCS |

| DN250 | 10PCS |

| DN315 | 10PCS |

***Export to many countries