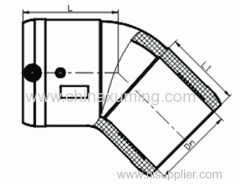

PE Electrio Fusion 45 Degree Elbow Pipe Fittings

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | XM-EF45E |

|---|---|

| Means of Transport: | Ocean, Air |

| Head Code: | Others |

| Shape: | Equal |

| Technics: | Others |

| Type: | Elbow |

| Material: | Plastic |

| Connection: | Welding |

| Brand Name: | OEM |

| Material: | HDPE80 or HDPE100 |

| Working Pressure: | SDR11 |

| Working Tempreture: | -40℃~40℃ |

| Connection: | Welding |

| Specifications: | DN40~DN560 |

| Working Medium: | Water,Oil,Gas |

| Color: | Black |

| Working Life: | More than 50 years |

| Packing: | Plastic bags and Cartons |

| Export Area: | All over the world |

| Production Capacity: | 100000pcs/month |

| Packing: | carton |

| Delivery Date: | 45 days |

Product Description

HDPE Electric Fusion 45 Degree Elbow

1. SPECIFICATIONS:

Specification | SDR Series | Dn | L1 | L |

Dn40 | SDR11 | 40 | 55 | 64 |

Dn50 | SDR11 | 50 | 57 | 74 |

Dn63 | SDR11 | 63 | 70 | 87 |

Dn75 | SDR11 | 75 | 72 | 86 |

Dn90 | SDR11 | 90 | 80 | 106 |

Dn110 | SDR11 | 110 | 86 | 115 |

Dn160 | SDR11 | 160 | 90 | 130 |

Dn200 | SDR11 | 200 | 105 | 154 |

Dn250 | SDR11 | 250 | 115 | 175 |

Dn315 | SDR11 | 315 | 130 | 205 |

Dn400 | SDR17.6/17 | 400 | 180 | 300 |

Dn450 | SDR17.6/17 | 450 | 205 | 323 |

Dn500 | SDR17.6/17 | 500 | 215 | 338 |

Dn560 | SDR17.6/17 | 560 | 235 | 368 |

2. ELECTRO-FUSION PROCESS

The following equipments and tools are required for the Electro fusion process:

A: Automatic Electro-fusion machine.

B: Power source compatible with the machine power.

C: Suitable pipe clamps.

D: Pipe cutter.

E: Electro fusion fittings with size similar to the pipe size.

F: Scrubbing tools.

G: Marker pen.

3. Basic performance of raw materials for pipe fittings

| Paramenter | Units | Requirement | Test Value |

| Density | kg/m³ | ≥930 | 23ºC |

| Melt flow rate | g/10min | 0.2~1.4 | 190ºC,5kg |

| Thermal slaility (OIT) | min | >20 | 200ºC |

| Volati lematter content | mg/kg | ≤350 | |

| Moisture content | mg/kg | ≤300 | ASTM D 4019:1994a |

| Carbon black content | % | 2.0~2.5 | |

| Crbon black dispersion | grade | ≤3 | |

| Gas proof components | h | ≥20 | 80ºC,2MPa(Hoop stress) |

Resistance to slow crack growth (En>5mm) | h | 165 | 80ºC,0.80MPa(Testing pressure) 80ºC,0.92MPa(Testing pressure) |

4. Performance requirement of pipe fittings

| NO. | Item | Requirement | Test value |

| 1 | 20ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 10.0MPa PE100 12.4MPa Testing temperature: 20ºC Testing time: ≥100h |

| 2 | 80ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 4.50MPa PE100 5.40MPa Testing temperature: 80ºC Testing time: ≥165h |

| 3 | 80ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 4.50MPa PE100 5.40MPa Testing temperature: 80ºC Testing time: ≥1000h |

| 4 | Tensile strength of butt-fusion pipe fittings | Test to destruction: Flexible is good | Testing temperature:23ºC±2ºC |

| 5 | Welding strength of electro-fusion | Percentage of brittle peel: ≤33.3% | Testing temperature:23ºC±2ºC |

| 6 | Oxidation induction time | >20min | 200ºC |

| 7 | Melt flow rate | Tube melt rate of change not exceeding ±20% of the raw material | 190ºC, 5kg |

We have 100,000 square meters of factory, including plastic injection workshop, mold workshop, CNC workshop, packaging workshop, raw material warehouse, finished products warehouse and office building.

The company has dozens of skilled researchers.

Welcome to our factory to visit.