HDPE Electrio Fusion Reducing Tee Pipe Fittings

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 100000/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | XM-EFRT |

|---|---|

| Means of Transport: | Ocean, Air |

| Head Code: | Others |

| Shape: | Equal |

| Technics: | Others |

| Type: | Tee |

| Material: | Plastic |

| Connection: | Welding |

| Brand Name: | OEM |

| Material: | HDPE80 or HDPE100 |

| Working Pressure: | SDR11 |

| Working Tempreture: | -40℃~40℃ |

| Connection: | Welding |

| Specifications: | DN20~DN315 |

| Working Medium: | Water,Oil,Gas |

| Color: | Black |

| Working Life: | More than 50 years |

| Packing: | Cartons |

| Export Area: | All over the world |

| Production Capacity: | 100000/month |

| Packing: | carton |

| Delivery Date: | 45 days |

Product Description

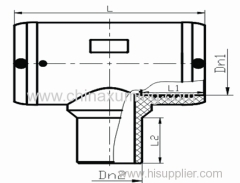

HDPE Electric Fusion Injection Reducing Tee

1. Specification:

Dn1xDn2 | SDR Series | Dn1 | Dn2 | L1 | L2 | L |

25x20 | SDR11 | 25 | 20 | 45 | 42 | 107 |

32x20 | SDR11 | 32 | 20 | 45 | 43 | 117 |

32x25 | SDR11 | 32 | 25 | 45 | 43 | 117 |

40x25 | SDR11 | 40 | 25 | 50 | 42 | 136 |

40x32 | SDR11 | 40 | 32 | 50 | 52 | 136 |

50x25 | SDR11 | 50 | 25 | 53 | 47 | 145 |

50x32 | SDR11 | 50 | 32 | 53 | 50 | 145 |

50x40 | SDR11 | 63 | 40 | 53 | 52 | 145 |

63x25 | SDR11 | 63 | 25 | 58 | 51 | 167 |

63x32 | SDR11 | 63 | 32 | 58 | 51 | 167 |

63x40 | SDR11 | 63 | 40 | 58 | 48 | 167 |

63x50 | SDR11 | 75 | 50 | 58 | 51 | 167 |

75x20 | SDR11 | 75 | 20 | 64 | 45 | 188 |

75x32 | SDR11 | 75 | 32 | 64 | 48 | 188 |

75x40 | SDR11 | 75 | 40 | 64 | 52 | 188 |

75x50 | SDR11 | 75 | 50 | 64 | 57 | 188 |

75x63 | SDR11 | 75 | 63 | 64 | 63 | 188 |

90x32 | SDR11 | 90 | 32 | 80 | 59 | 227 |

90x40 | SDR11 | 90 | 40 | 80 | 65 | 227 |

90x50 | SDR11 | 90 | 50 | 80 | 66 | 227 |

Dn1xDn2 | SDR Series | Dn1 | Dn2 | L1 | L2 | L |

90x63 | SDR11 | 90 | 63 | 80 | 67 | 227 |

110x32 | SDR11 | 110 | 32 | 85 | 69 | 256.5 |

110x40 | SDR11 | 110 | 40 | 85 | 74 | 256.5 |

110x50 | SDR11 | 110 | 50 | 85 | 69 | 256.5 |

110x63 | SDR11 | 110 | 63 | 85 | 77 | 256.5 |

110x75 | SDR11 | 110 | 75 | 85 | 73 | 256.5 |

110x90 | SDR11 | 110 | 90 | 85 | 85 | 256.5 |

160x63 | SDR11 | 160 | 63 | 119 | 63 | 370 |

160x90 | SDR11 | 160 | 90 | 119 | 103 | 370 |

160x110 | SDR11 | 160 | 110 | 119 | 100 | 370 |

200x110 | SDR11 | 200 | 110 | 124 | 82 | 400 |

200x160 | SDR11 | 200 | 160 | 124 | 99 | 400 |

250x90 | SDR11 | 250 | 90 | 130 | 80 | 487 |

250x110 | SDR11 | 250 | 110 | 130 | 83 | 487 |

250x160 | SDR11 | 250 | 160 | 130 | 99 | 487 |

250x200 | SDR11 | 250 | 200 | 130 | 113 | 487 |

315x110 | SDR11 | 315 | 110 | 150 | 83 | 588 |

315x160 | SDR11 | 315 | 160 | 150 | 99 | 588 |

315x200 | SDR11 | 315 | 200 | 150 | 113 | 588 |

315x250 | SDR11 | 315 | 250 | 150 | 130 | 588 |

2. Product features.

>Material: 100% new material PE80 or PE100

>Working Medium: Water and Gas

>Working Pressure: SDR11

>Working Temperature: -40℃~40℃

>Specifications: Dn25x20x25 ~ Dn315x250x315

>New mould and scientific design

>Competitive price and accept OEM

>Recycled and Environment-friendly

>Color: black or other colors on request

>Guarantee period : more than 50 years under proper use

3. Basic performance of raw materials for pipe fittings

| Paramenter | Units | Requirement | Test Value |

| Density | kg/m³ | ≥930 | 23ºC |

| Melt flow rate | g/10min | 0.2~1.4 | 190ºC,5kg |

| Thermal slaility (OIT) | min | >20 | 200ºC |

| Volati lematter content | mg/kg | ≤350 | |

| Moisture content | mg/kg | ≤300 | ASTM D 4019:1994a |

| Carbon black content | % | 2.0~2.5 | |

| Crbon black dispersion | grade | ≤3 | |

| Gas proof components | h | ≥20 | 80ºC,2MPa(Hoop stress) |

Resistance to slow crack growth (En>5mm) | h | 165 | 80ºC,0.80MPa(Testing pressure) 80ºC,0.92MPa(Testing pressure) |

4. Performance requirement of pipe fittings

| NO. | Item | Requirement | Test value |

| 1 | 20ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 10.0MPa PE100 12.4MPa Testing temperature: 20ºC Testing time: ≥100h |

| 2 | 80ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 4.50MPa PE100 5.40MPa Testing temperature: 80ºC Testing time: ≥165h |

| 3 | 80ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 4.50MPa PE100 5.40MPa Testing temperature: 80ºC Testing time: ≥1000h |

| 4 | Tensile strength of butt-fusion pipe fittings | Test to destruction: Flexible is good | Testing temperature:23ºC±2ºC |

| 5 | Welding strength of electro-fusion | Percentage of brittle peel: ≤33.3% | Testing temperature:23ºC±2ºC |

| 6 | Oxidation induction time | >20min | 200ºC |

| 7 | Melt flow rate | Tube melt rate of change not exceeding ±20% of the raw material | 190ºC, 5kg |