PPR Long Male Threaded Union Pipe Fittings With CE Certificate

| Min. Order: | 10 Pack/Packs |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 100000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | XM-PPR024 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Head Code: | Others |

| Shape: | Equal |

| Technics: | Others |

| Type: | Union |

| Material: | PP-R |

| Connection: | Male |

| Brand Name: | OEM |

| Working Medium: | Water Systems |

| Working Pressure: | 2.50MPa |

| Working Temperature: | 95℃ |

| Connector: | Male Thread |

| Color: | Green, Grey, White |

| Specification: | Dn20x1/2,DN25x3/4,DN32x1 |

| Process: | Injection Moulding |

| Export Area: | Russia,Middle East,Asia |

| Delivery Time: | Within 30 days |

| Port of Loading: | Ningbo or Shanghai |

| Production Capacity: | 100000pcs/month |

| Packing: | cartons |

| Delivery Date: | 30 days |

Product Description

PPR Long Male Threaded Union Pipe Fittings With CE Certificate

***SPECIFICATIONS

| |||

| Size | Net Weight(g) | PCS/CTN | MOQ(cartons) |

| 20x1/2" | 128g | 270 | 10 |

| 25x3/4" | 196g | 180 | 10 |

| 32x1" | 317g | 108 | 10 |

PPR Long Male Threaded Union Pipe Fittings in addition to general plastic tube with a light weight , corrosion , scaling , long life and other characteristics, but also has the following main features:

1.Non-toxic , health . PPR raw molecules only carbon and hydrogen elements , no harmful toxic elements are present , reliable health, not only for the hot and cold water pipes , but also for pure drinking water systems .

2.Thermal insulation . PPR pipe thermal conductivity 0.21w/mk, steel is only 1/200.

3.Preferably heat resistance. Vicat softening point PPR pipe 131.5 ℃. The maximum operating temperature of up to 95 ℃, water supply and drainage construction to meet the requirements of the specification using hot water system .

4.Long life . PPR pipe operating temperature 70 ℃, working pressure (PN) 1.OMPa conditions , the service life up to 50 years ; room temperature (20 ℃) life of up to 100 years.

5.Easy to install , reliable connection . PPR has good weldability, pipes, fittings can be melt and fused connection , easy to install , reliable joints connecting parts is greater than the strength of the strength of the pipe itself .

6.The material is recyclable . PPR waste cleaned , crushed and recycled in pipe, tube production . Recycled material

The amount does not exceed 10% of the total , does not affect product quality.

**Use of Green PPR Coupling Pipe Fittings

1, building hot and cold water systems, including central heating systems;

2, the building heating system, including flooring, siding and radiant heating systems;

3, can be directly purified drinking water supply systems;

4, Central (centralized) air-conditioning systems;

5, transfer or discharge of chemical mediators such as industrial piping systems.

***Reference Table of Melt Connection Technology

Reference Table of Melt Connection Technology | ||||

| Pipe Diameter | Welding Depth | Heating Time | Processing Time | Cooling Time |

| mm | mm | Second | Second | Minutes |

| 20x2.8 | 14 | 5 | 4 | 2 |

| 25x3.5 | 15 | 7 | 4 | 2 |

| 32x4.4 | 17 | 8 | 6 | 4 |

| 40x5.5 | 19 | 12 | 6 | 4 |

| 50x6.9 | 21 | 18 | 6 | 5 |

| 63x8.7 | 24 | 24 | 8 | 6 |

| 75x10.3 | 27 | 30 | 8 | 8 |

| 90x12.3 | 29 | 40 | 8 | 8 |

| 110x15.1 | 32 | 50 | 10 | 8 |

| 125x18.0 | 35 | 60 | 10 | 9 |

| Note: If the ambient temperature is less than 5, the heating time increased by 50% | ||||

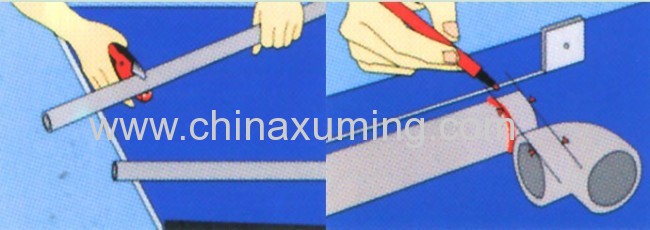

***WELDING STEPS OF PPE PIPES AND PPR PIPE FITTINGS:

1.Cut pipe

When you disconnect the pipe, you must use the tube cutter vertical cut, because if there is no tube cutter, use other tools Xiaoduan pipe, after cutting off the head should be cleaned, insert the support sleeve.

2.Heating pipes and pipe fittings

When the tube is heated to fusion 260 ℃, while advancing the pipes and fittings in the welding device,

and heated to 5 seconds or more.

3.Connecting pipes and pipe fittings

The heated vertical pipe and pipe fittings to promote and maintain more than 5 seconds, do not overexert when advancing to

prevent the tube head bent.

(1).After construction is subject to acceptance pressure test before being sealed tube and use.

(2).Connecting water pipes and equipment should be installed in the device. Pump or fan coil and a

receiver box must hose.

(3).When using a hot and cold water pipes, should take into account changes in thermal expansion and contraction.

(5).Insulation measures should not be direct contact between the pipe and the hanger. Hanger spacing

shall meet the following criteria:

(6).PP-R pipe hanger installation spacing

A:Cold water pipe hanger installation maximum spacing

| Nominal Diameter | 20mm | 35mm | 32mm | 40mm | 50mm | 63mm | 75mm | 90mm | 110mm |

| Horizontal Pipe | 0.65 | 0.80 | 0.95 | 1.10 | 1.25 | 1.40 | 1.50 | 1.60 | 1.90 |

| Risers | 1.00 | 1.20 | 1.50 | 1.70 | 1.80 | 2.00 | 2.00 | 2.00 | 2.50 |

B:Hot water pipe hanger installation maximum spacing

| Nominal Diameter | 20mm | 35mm | 32mm | 40mm | 50mm | 63mm | 75mm | 90mm | 110mm |

| Horizontal Pipe | 0.50 | 0.60 | 0.70 | 0.80 | 0.90 | 1.00 | 1.10 | 1.20 | 1.50 |

| Risers | 0.90 | 1.00 | 1.20 | 1.40 | 1.60 | 1.70 | 1.70 | 1.80 | 2.00 |

(6).As for the hot water pipes should increase the contact area between the bracket and the pipe.

(7).Installation location of various types of valves, import and export orientation must meet the design requirements, opening and

closing a flexible, easy to operate.

(8).Fill pipe should be installed on a one-way valve, the highest point of the system should be set to automatically release valve, inlet

and outlet connections shutoff valve must be installed.

(9).Import and export pumps near the tank should be installed thermometers, pressure gauges, filters and other components too

***PPR WELDING MACHINES AND PPR PIPES CUTTERS