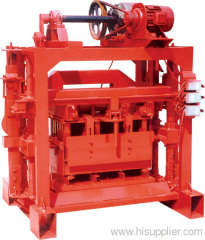

foam concrete brick making machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Place of Origin: | Hunan |

Company Profile

| Location: | Changsha, Hunan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Foam Concrete Machine, Foam Concrete Block Making Machine, Foaming Agent |

Product Detail

| Model No.: | FM-25 |

|---|---|

| Means of Transport: | Ocean |

| Style: | Others |

| Height: | Others |

| Processing: | Others |

| Material: | Cement |

| Material Feature: | Heat Insulation |

| Usage: | Wall |

| Color: | Blue |

| Brand Name: | Trinity |

| Packing: | wooden |

| Delivery Date: | 25days |

Product Description

1. Structure

FM-25 includes four parts, a belt conveyor, a mixer, a pump and a built-in foam generator inside the pump. The equipment is easy to install, dismantle, transport, and construct at site. The equipment has been fully debugged in factory. After assembling the three parts and hose, it is ready to use after plug the power.

2. Features

1) Dual-cylinder hydraulic propelling system with high discharge pressure, the machine can pump to high rise building floors. It reduces labor intensity.

2) Raw material input ratio is semi-automatic; therefore, foam concrete density is only a button press process.

3) Siemens motor and superior quality parts, guaranteed stable quality;

4) Domestic and oversees training services available

5) Superior quality foaming agent, low construction cost.

6) Flexible mobile and positioning ability with wheels,

7) Unique pump head, easy to dismantle and clean

8) 500L mixer and high power motor, fast mixing and large output. Unique mixer blade design, no damage to the foam. Saves foaming agent dosage while enhancing foam concrete quality.

9) It is applicable for both making foam concrete products and on-site casting.

10) 80 meters long casting hose, saves labor cost and reaches high rise building casting needs.

11) It is capable of casting foam concrete with sand content. Cheap sand reduces production cost.

12) Convenient design, decent paint and appearance.

3. Work Flow

4. Application Area

Floor/roof casting

Block

Wall panel

Framed wall and house structure casting

Subway and coal mining backfill

5. Technical Parameter:

Term | Unit | FM-25 |

Power | kw | 30 |

Max. Productivity | m3/h | 25 |

Vertical Delivery Distance | m | 80 |

Horizontal Delivery Distance | m | 300 |

Pumping Pressure | Mpa | 5 |

Conveyor Belt Dimension (L×W×H) | mm | 3250/800/450 |

Mixer Dimension (L×W×H) | mm | 2800/1500/900 |

Pump Dimension (L×W×H) | mm | 3800×1500×1500 |

Weight | kg | 1800 |