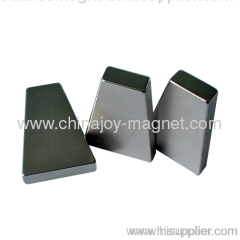

Ferrite Magnets Hard Ferrite Block Magnet

0.2~10.0 USD

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Metric Ton/Metric Tons per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Hard Ferrite Block Magnet. |

|---|---|

| Means of Transport: | Ocean |

| Type: | Permanent |

| Application:: | Inductors,Transformers, |

| Shape: | Block |

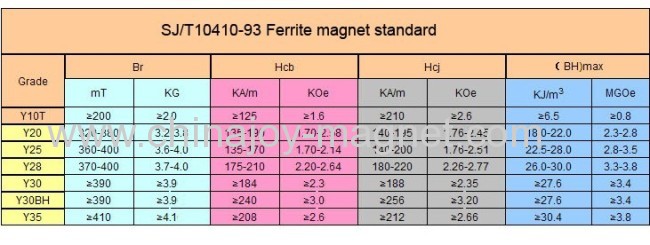

| Grade: | Y10T, Y20, Y25, Y30, Y30BH, Y35. |

| Size: | Custom Request |

| Place of Origin: | Zhejiang,China (Mainland) |

| Export Area: | All of the World |

| Cutting Tolerance: | +/-0.5mm |

| Magnetization: | Through thickness |

| Brand Name: | No |

| Production Capacity: | 100 Metric Ton/Metric Tons per Month |

| Packing: | According to customer's requirement |

| Delivery Date: | 15-20 days |

Product Description

High quality Ferrite Magnets

Advantage:

1)High magnetic flux density,

2)Excellent corrosion resistance

3)Raw material is readily available, low in cost

Advantage:

1)High magnetic flux density,

2)Excellent corrosion resistance

3)Raw material is readily available, low in cost

Ceramic magnetic material is made of a composite of iron oxide and barium/strontium carbonate.

The material is one of the most cost effective magnetic materials maunfactured in industry. The low cost is due to the cheap, abundant, and nonstrategic raw material lend themselves to large production runs. This magnetic material has a fair to good resistance to corrosion and it can operate in moderate heat.

Application:

Ceramic magnets can be found in a wide variety of applications. Motors Loudspeakers Separators

Ferrite Magnetic Assemblies designed for lifting, holding and retrieving.

PRODUCT DETAILS:

Product Description:

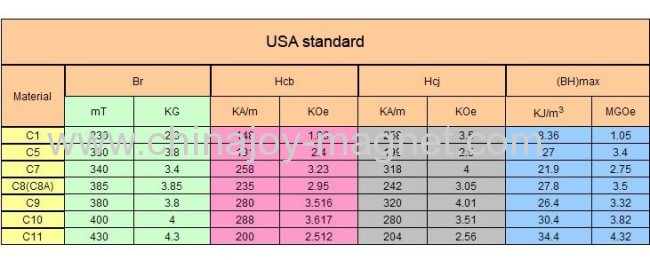

Ceramic magnets, also known as ferrite magnets, is a type of permanent magnets made of iron oxide and strontium carbonate. we carry the grade C8 ceramic magnets, which is the strongest ceramic magnet. Ceramic magnets are widely used as craft magnets and refrigerator magnets.

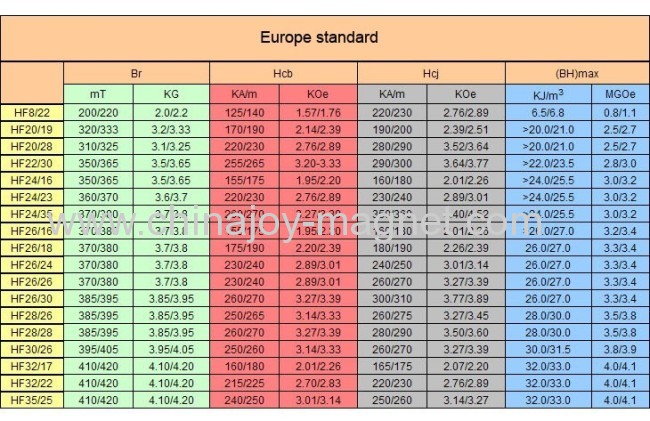

TECHNOLOGY PARAMETERS

.jpg)

.jpg)