permanent magnet sintered NdFeB magnets N35 to N50 different grades

1.0~10.0 USD

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Supply Ability: | 100 Metric Ton/Metric Tons per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | sintered NdFeB |

|---|---|

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Application: | Industrial Magnet |

| Shape: | Arc, block, ring, disc |

| Grade: | From N35 to N50 and other grades are available |

| Platings: | Nickel |

| Place of Origin: | Zhejiang, China (Mainland) |

| Tollerance: | +/-0.05mm |

| Size: | Custom Request |

| Export Area: | All of the World |

| Production Capacity: | 100 Metric Ton/Metric Tons per Month |

| Packing: | According to customer's requirement |

| Delivery Date: | 15-20 days |

Product Description

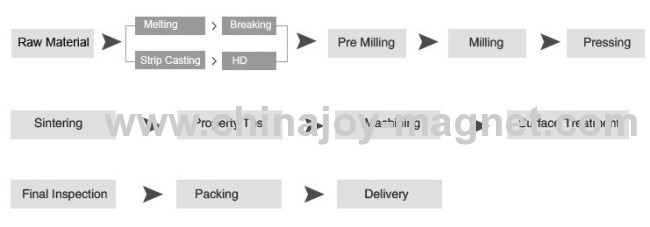

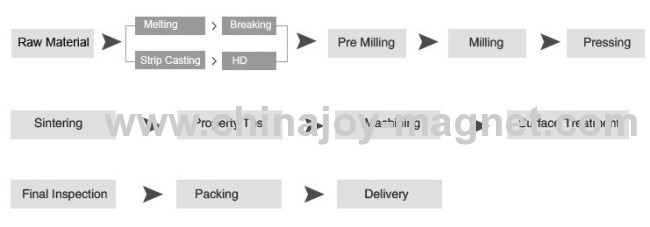

Production Process:

NdFeB Segment, ZN coating, mainly used in auto parts, such as Motors etc.

Coating can be:Phosphate Ni, NICUNI , bright NI, Dark Ni, Chemical NI, Zn ,

Blue Zn, Color Zn, Gold, Silver, , Epoxy, NI+ Epoxy, Zn+ Epoxy, parylene, etc

Product Photo:

Neodymium Iron Boron (NdFeB) magnets, the most powerful permanent magnets available today, possess high energy up to 52MGOe and wonderful coercive force.

1. Primary Material: Neodymium, iron, boron, rare-earth material

2. Maximum working temperature: 80-220 degree celcius

3. Density: 7.5 to 7.6g/CMM³

4. Application: Motors, Windmill, Acoustics, Magnetic separators, Auto, VCM, MRI, Mobile accessories

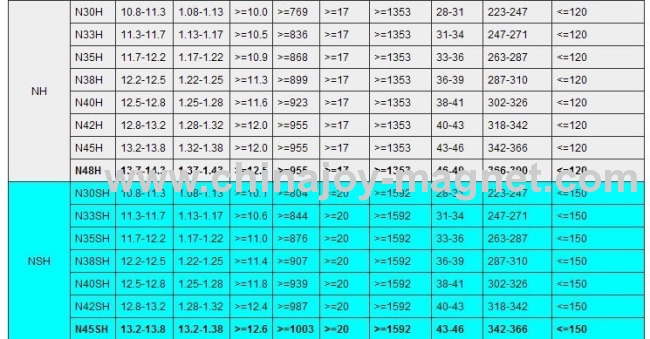

5. Grade available:

N35-N52, N33M-N50M, N30H-N48H, N30SH-N45SH, N28UH-N40UH, N328EH-N35EH, N30AH-N33AH

Strong Neodymium Iron Boron Magnet

Magnetic properties of main grades

Product Photo:

Neodymium Iron Boron (NdFeB) magnets, the most powerful permanent magnets available today, possess high energy up to 52MGOe and wonderful coercive force.

1. Primary Material: Neodymium, iron, boron, rare-earth material

2. Maximum working temperature: 80-220 degree celcius

3. Density: 7.5 to 7.6g/CMM³

4. Application: Motors, Windmill, Acoustics, Magnetic separators, Auto, VCM, MRI, Mobile accessories

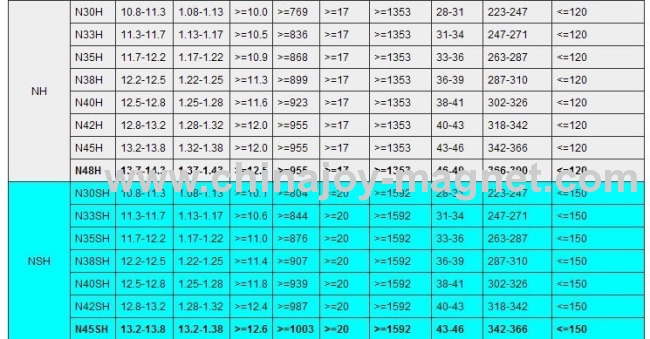

5. Grade available:

N35-N52, N33M-N50M, N30H-N48H, N30SH-N45SH, N28UH-N40UH, N328EH-N35EH, N30AH-N33AH

Strong Neodymium Iron Boron Magnet

- High remanence, high coercive force, high energy, etc

- High resistance to magnetic demagnetization

- Excellent cost to performance ratio

- Not suitable for application which exposed to high temperatures.

- Widely used in mini-motors, wind generators, meters, sensors, speakers, magnetic suspension system, magnetic transmission machine and other industrial applications.

- Very easy to corrosion in humid environments, so it is necessory to do the surface treatment according customers' requirements. We can offer the coatings, such as Zinc, Nickel, Nickel-copper-nickel, Silver, gold-plating, Epoxy coating, etc

Magnetic properties of main grades