Custom Order Magnetic Drum Separators

5.0~200.0 USD

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Metric Ton/Metric Tons per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Magnetic Drum Separators |

|---|---|

| Means of Transport: | Ocean |

| Type: | Permanent |

| Composite: | Custom Magnetic Assemblies |

| Application: | Industrial Magnet |

| Shape: | According to Drawing |

| Grade: | N35-N52,(M,H,SH,UH,EH) |

| Platings: | Ni,Zn,Au,CU |

| Place of Origin: | Zhejiang, China (Mainland) |

| Export Area: | All of the World |

| Brand Name: | Joy or OEM |

| Production Capacity: | 100 Metric Ton/Metric Tons per Month |

| Packing: | According to customer's requirement |

| Delivery Date: | 15-20 days |

Product Description

Magnetic Drum Separators

Introduction:

Magnetic Drum Separators are of self-cleaning type and provide continuous removal of ferrous contaminations from a wide range of free-flowing bulk and granular materials in high-volume applications.

These are widely used in all the processing industry for separation of iron contamination from:

·Minerals and Chemicals

·Food and Flour

·Plastics

·Grains

·Sand

·Fertilizers

·Abrasives

·Glass

·Slag

·Ores

·Rock

·Refractory

Advantages:

Construction:How does it work?

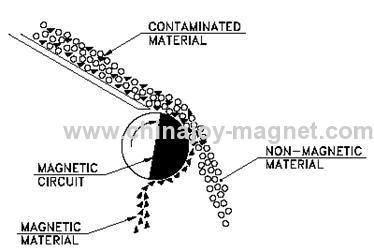

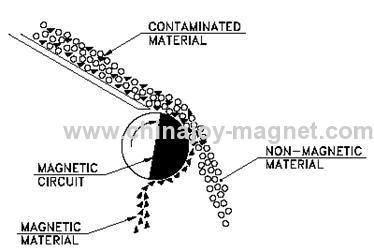

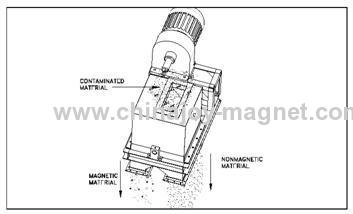

As material reaches the drum, the magnetic field attracts and holds ferrous particles to the drum shell. As the drum revolves, it carries the material through the stationary magnetic field. The nonmagnetic material falls freely from the shell, while ferrous particles are held firmly until they are carried out of the magnetic field by interrupters / cleats. The tramp metal is discharged separately, creating continuous self-cleaning separation. The end result is purified product ready for processing without the worry of costly damage caused by tramp metal.

Features:

·Designed for continuous separation and self cleaning. Ideal for high-flow, heavy-contamination applications. It comes with Stainless steel drum and mild steel or stainless steel housings.

·Maximum Recovery of Ferrous Metals.

·Minimum Maintenance.

·They require minimum space and are simple to operate.

·They are flexible enough to be applied for various purposes

Specifications:

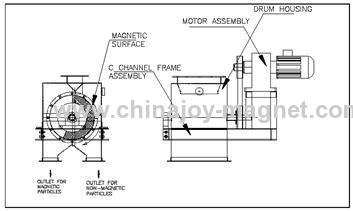

·Drums can be ordered with or without housing.

·Magnetic Drum Separator system is a complete machine with Stainless Steel 304 / 316 Housing & Drive system. Only drum separator unit can also be supplied.

·The Drum Separators are available in two types:

A.High Intensity – (Ndfeb Magnet – 4500 gauss)

B.Low Intensity - (Ferrite Magnet - 1200 gauss)

·Ferrous fine particles, nuts, bolts, pins, nails and other tramp metal from free-flowing granular material can be arrested effectively.

·Round, Square, and Rectangular spouting, as desired can be provided.

·Besides customized Drum Separators, PML also supplies Standard Separators as below:

Sr | Standard Sizes in mm |

1 | Diameter 300x300 Length |

2 | Diameter 300x450 Length |

3 | Diameter 450x600 Length |

4 | Diameter 500x750 Length |

Advantages:

- Helps in removing ferrous particles from any non ferrous powder and granules.

- Ideal for plastic, food, fertilizer, pharmaceutical, chemical, glass and continuous process plants.

- Provide utmost protection to crushers, grinders, pulverizes, and allied equipment.

- Can be used for mining and ore dressing industry.

- Eliminate fire hazards and explosions in plants dealing with explosive material.

- Saves money, time and labor by reducing break-down time and improving the quality.

The magnetic drum separator consists of a rotating drum and stationary magnetic circuit designed as per the specific need of the customer. The Drum separator is supplied with Drive system and SS 304/316 housing along with feed regulating valve.

Why Choose Our drum Separator?

·Rich experience in design and development of Permanent Magnets and Magnetic Systems.

·Magnet Drum Separators are available in wide range from 1200 Gauss (up to 250°C) to high intensity 4500 Gauss (upto 80°C).

·Customized Design.

·We offers comprehensive systems using 2/3 drum separators with other magnetic systems in series to ensure output contamination level to minimum PPM.

·Services such as magnetic calibration/Audit are available.

Information required for design of magnetic drum separator

·Type of material from which Iron is to be separated. (Sticky, Granular, Free flowing, Lumps etc).

·Size and level/percentage of contamination.

·Flow rate of material.

·Size/Density of the material particle.

.jpg)