N35 Arc Ndfeb Magnet Motors with ni coating

1.0~50.0 USD

| Min. Order: | 10000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Metric Ton/Metric Tons per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | N35 Arc Ndfeb Magnet |

|---|---|

| Means of Transport: | Ocean, Air |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Application: | Moto Magnet |

| shape: | Arc |

| Grade: | N35 |

| Platings: | Ni |

| Place of Origin: | Zhejiang, China (Mainland) |

| Brand Name: | Joy |

| Product Name: | NdFeB Magnet Arc |

| Function: | magnetic extractor |

| Production Capacity: | 100 Metric Ton/Metric Tons per Month |

| Packing: | According to customer's requirement |

| Delivery Date: | 15-20 days |

Product Description

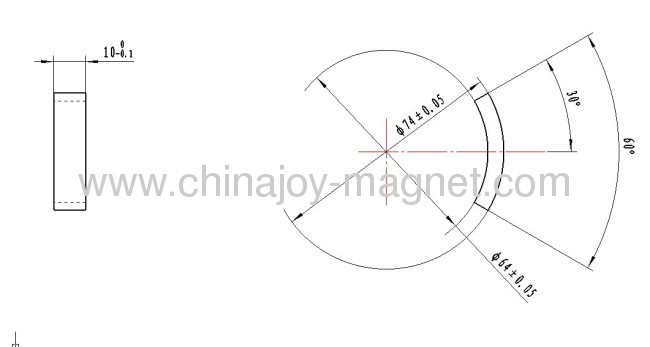

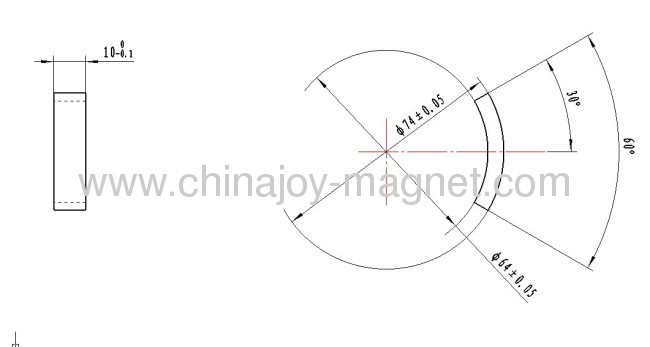

Drawings:

Product Name: Motor Magnet, Segment, Arc ndfeb magnet, Arc Magnets.Tile NdFeB Magnet

Product Name: Motor Magnet, Segment, Arc ndfeb magnet, Arc Magnets.Tile NdFeB Magnet

It is one special shape of Rare earth magnets and permanent magnets. It is always manufactured via Wire Cutting and grinding etc. Regular Arc magnets or Segment magnets have the following important factors such as, Outer Diameter or Outer Radius, Inner Diameter or Inner Radius, Degree of Angle, Thickness, Length, Round Edge etc.

Applications:

Motors, eg. voice coil motor (VCM),step motor, geared down motor, etc.

Features:

Generally speaking, Arc Magnets are all made as Customer Design and as Special requirement. Our factory production and manufacture magnets according to customer's design on shape, dimension, grades, coatings etc.

Magnets grade: From N35 to N50, from N Series to UH Series.

Magnets drawing with size and shape and different side view

Magnetism direction: Mostly magnetized via diameter, if special magnetism direction, please show on the drawing in advance.

Magnets coating: Nickel, Zn, Black Epoxy, Black Nickel ,Nickel -Cu-Nickel,Ag, Au etc.

Quantities: More mass order quantities. More lower the prices. Original manufacture.

For more informations about above magnetism requirement, please visit our website .

NdFeB Magnetof Magnetic grade :

Magnets grade: From N35 to N50, from N Series to UH Series.

Magnets drawing with size and shape and different side view

Magnetism direction: Mostly magnetized via diameter, if special magnetism direction, please show on the drawing in advance.

Magnets coating: Nickel, Zn, Black Epoxy, Black Nickel ,Nickel -Cu-Nickel,Ag, Au etc.

Quantities: More mass order quantities. More lower the prices. Original manufacture.

For more informations about above magnetism requirement, please visit our website .

NdFeB Magnetof Magnetic grade :

Grade | BrmT(kGs) | HcbkA/m(kOe) | Hcj kA/m (kOe) | (BH)max kJ/m3 (MGOe) | Supreme work temperature(Tw) |

N33 | 1130-1170(11.3-11.7) | ≥ 836 ( ≥ 10.5) | ≥ 955( ≥ 12) | 247-271(31-34) | 80 ℃ |

N35 | 1170-1220(11.7-12.2) | ≥ 868( ≥ 10.9) | ≥ 955( ≥ 12) | 263-287(33-36) | 80 ℃ |

N38 | 1220-1250(12.2-12.5) | ≥ 899( ≥ 11.3) | ≥ 955( ≥ 12) | 287-310(36-39) | 80 ℃ |

N40 | 1250-1280(12.5-12.8) | ≥ 907( ≥ 11.4) | ≥ 955 ( ≥ 12) | 302-326(38-41) | 80 ℃ |

N42 | 1280-1320(12.8-13.2) | ≥ 915( ≥ 11.5) | ≥ 955( ≥ 12) | 318-342(40-43) | 80 ℃ |

N45 | 1320-1380(13.2-13.8) | ≥ 923( ≥ 11.6) | ≥ 955 ( ≥ 12) | 342-366(43-46) | 80 ℃ |

N48 | 1380-1420(13.8-14.2) | ≥ 923( ≥ 11.6) | ≥ 876( ≥ 12) | 366-390(46-49) | 80 ℃ |

N50 | 1400-1450(14.0-14.5) | ≥ 796( ≥ 10.0) | ≥ 876( ≥ 11) | 382-406(48-51) | 60 ℃ |

N52 | 1430-1480(14.3-14.8) | ≥ 796( ≥ 10.0) | ≥ 876( ≥ 11) | 398-422(50-53) | 60 ℃ |

30M | 1080-1130(10.8-11.3) | ≥ 796( ≥ 10.0) | ≥ 1114 ( ≥ 14) | 223-247(28-31) | 100 ℃ |

33M | 1130-1170(11.3-11.7) | ≥ 836( ≥ 10.5) | ≥ 1114( ≥ 14) | 247-263(31-33) | 100 ℃ |

35M | 1170-1220(11.7-12.2) | ≥ 868( ≥ 10.9) | ≥ 1114( ≥ 14) | 263-287(33-36) | 100 ℃ |

38M | 1220-1250(12.2-12.5) | ≥ 899( ≥ 11.3) | ≥ 1114( ≥ 14) | 287-310(36-39) | 100 ℃ |

40M | 1250-1280(12.5-12.8) | ≥ 923( ≥ 11.6) | ≥ 1114( ≥ 14) | 302-326(38-41) | 100 ℃ |

42M | 1280-1320(12.8-13.2) | ≥ 955( ≥ 12.0) | ≥ 1114( ≥ 14) | 318-342(40-43) | 100 ℃ |

45M | 1320-1380(13.2-13.8) | ≥ 995( ≥ 12.5) | ≥ 1114 ( ≥ 14) | 342-366 (43-46) | 100 ℃ |

48M | 1360-1430(13.6-14.3) | ≥ 1027( ≥ 12.9) | ≥ 1114( ≥ 14) | 366-390(46-49) | 100 ℃ |

50M | 1400-1450(14.0-14.5) | ≥ 1033 ( ≥ 13.0) | ≥ 1114( ≥ 14) | 382-406(48-51) | 100 ℃ |

30H | 1080-1130(10.8-11.3) | ≥ 796 ( ≥ 10.0) | ≥ 1353( ≥ 17) | 223-247(28-31) | 120 ℃ |

33H | 1130-1170(11.3-11.7) | ≥ 836 ( ≥ 10.5) | ≥ 1353( ≥ 17) | 247-271(31-34) | 120 ℃ |

35H | 1170-1220(11.7-12.2) | ≥ 868 ( ≥ 10.9) | ≥ 1353( ≥ 17) | 263-287(33-36) | 120 ℃ |

38H | 1220-1250(12.2-12.5) | ≥ 899 ( ≥ 11.3) | ≥ 1353 ( ≥ 17) | 287-310(36-39) | 120 ℃ |

40H | 1250-1280(12.5-12.8) | ≥ 923( ≥ 11.6) | ≥ 1353( ≥ 17) | 302-326(38-41) | 120 ℃ |

42H | 1280-1320(12.8-13.2) | ≥ 955 ( ≥ 12.0) | ≥ 1353( ≥ 17) | 318-342(40-43) | 120 ℃ |

45H | 1300-1360(13-13.6) | ≥ 963( ≥ 12.1) | ≥ 1353 ( ≥ 17) | 326-358(43-46) | 120 ℃ |

48H | 1370-1430(13.7-14.3) | ≥ 995( ≥ 12.5) | ≥ 1353( ≥ 17) | 366-390(46-49) | 120 ℃ |

30SH | 1080-1130(10.8-11.3) | ≥ 804( ≥ 10.1) | ≥ 1592( ≥ 20) | 223-247(28-31) | 150 ℃ |

33SH | 1130-1170(11.3-11.7) | ≥ 844( ≥ 10.6) | ≥ 1592( ≥ 20) | 247-271(31-34) | 150 ℃ |

35SH | 1170-1220(11.7-12.2) | ≥ 876 ( ≥ 11.0) | ≥ 1592( ≥ 20) | 263-287(33-36) | 150 ℃ |

38SH | 1220-1250(12.2-12.5) | ≥ 907( ≥ 11.4) | ≥ 1592( ≥ 20) | 287-310(36-39) | 150 ℃ |

40SH | 1240-1280(12.5-12.8) | ≥ 939( ≥ 11.8) | ≥ 1592( ≥ 20) | 302-326(38-41) | 150 ℃ |

42SH | 1280-1320(12.8-13.2) | ≥ 987 ( ≥ 12.4) | ≥ 1592 ( ≥ 20) | 318-342(40-43) | 150 ℃ |

45SH | 1320-1380(13.2-13.8) | ≥ 1003 ( ≥ 12.6) | ≥ 1592( ≥ 20) | 342-366 (43-46) | 150 ℃ |

28UH | 1020-1080 (10.2-10.8) | ≥ 764 ( ≥ 9.6) | ≥ 1990 ( ≥ 25) | 207-231(26-29) | 180 ℃ |

30UH | 1080-1130 (10.8-11.3) | ≥ 812( ≥ 10.2) | ≥ 1990( ≥ 25) | 223-247(28-31) | 180 ℃ |

33UH | 1130-1170(11.3-11.7) | ≥ 852( ≥ 10.7) | ≥ 1990 ( ≥ 25) | 247-271(31-34) | 180 ℃ |

35UH | 1180-1220 (11.8-12.2) | ≥ 860 ( ≥ 10.8) | ≥ 1990( ≥ 25) | 263-287(33-36) | 180 ℃ |

38UH | 1220-1250(12.2-12.5) | ≥ 876 ( ≥ 11.0) | ≥ 1990( ≥ 25) | 287-310(36-39) | 180 ℃ |

40UH | 1240-1280 (12.5-12.8) | ≥ 899( ≥ 11.3) | ≥ 1990( ≥ 25) | 302-326(38-41) | 180 ℃ |