cast block alnico magnet

0.5~5.0 USD

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Metric Ton/Metric Tons per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

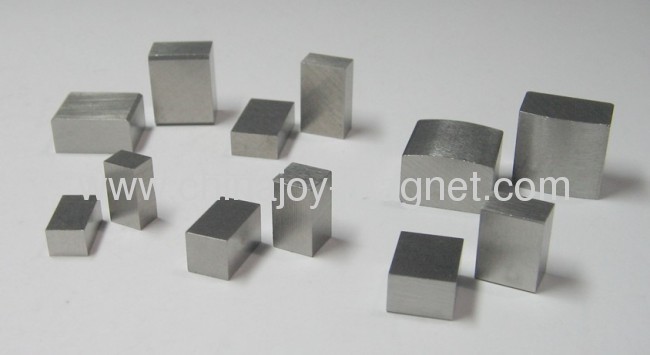

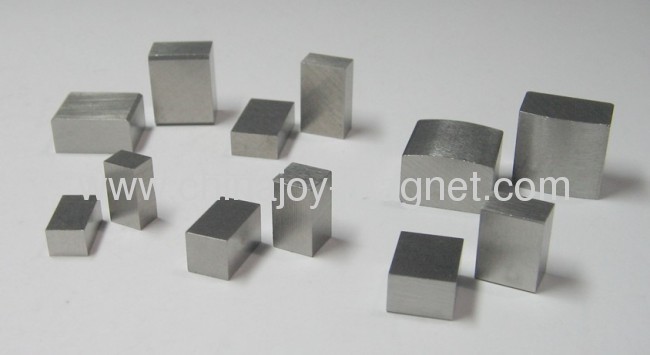

| Model No.: | cast block alnico |

|---|---|

| Means of Transport: | Ocean |

| Type: | Permanent |

| Application: | Industrial Magnet |

| Shape: | Rod,block,ring,cylinder,unregular |

| Grade: | AlNiCo 2,AlNiCo 3,AlNico 5,AlNiCo 8,AlNiCo 5-7,AlNiCo8H,AlNiCo 9 |

| Place of Origin: | Zhejiang, China(Mainland) |

| Export Area: | All of the World |

| Cutting Tolerance: | +/-0.05mm |

| Magnetization: | Custom Request |

| Brand Name: | Joy |

| Platings: | Ni,Zn,Au,CU |

| Production Capacity: | 100 Metric Ton/Metric Tons per Month |

| Packing: | According to customer's requirement |

| Delivery Date: | 15-20 days |

Product Description

1. Name: Alnico Block Magnet.

2. Characteristics: Compact crystal, high intensity, goodchemistry stability, stong anti-corrosion, even elements, exceelent and magneticperformance, excellent temperature stability, highest usage temperature reach500 degree.

3. Quality control: ISO9001:2000, SGS stardard.

4. Material grade:LN10/LNG13/LNGT18/LNG37/LNG40/LNG44/LNG52/LNG60/

LNGT28/LNGT36J/LNGT38/LNGT40/LNGT60/LNG72

product name: Alnico Magnets

Alnicos are precipitation-hardened alloys requiring special heat treatment techniques. The raw materials are Cobalt, Nickel, Copper, Aluminum and Iron. Titanium, silicon, etc. are added in certain proportions. The raw materials in their purest form are melted in medium frequency induction furnaces and castings are made using conventional sand or shell moulds. The heat treatment consists of heating the alloy in furnace to well above its curie point, and holding it at that temperature for some time. This is followed by controlled cooling after which the castings are reheated and held for a long period at a temperature of about 600°C. This ageing process increases the coercive force and the energy product. Finally, the castings are ground to obtain close dimensional tolerances whenever necessary and inspected for physical and magnetic accuracy.

The Characteristics of Alnico Magnet:

product name: Alnico Magnets

Alnicos are precipitation-hardened alloys requiring special heat treatment techniques. The raw materials are Cobalt, Nickel, Copper, Aluminum and Iron. Titanium, silicon, etc. are added in certain proportions. The raw materials in their purest form are melted in medium frequency induction furnaces and castings are made using conventional sand or shell moulds. The heat treatment consists of heating the alloy in furnace to well above its curie point, and holding it at that temperature for some time. This is followed by controlled cooling after which the castings are reheated and held for a long period at a temperature of about 600°C. This ageing process increases the coercive force and the energy product. Finally, the castings are ground to obtain close dimensional tolerances whenever necessary and inspected for physical and magnetic accuracy.

The Characteristics of Alnico Magnet:

*Small changes in magnetic properties to temperature effects

*Maximum working temperature can be as high as 450oC~550oC.

*Low coercive force.

*Strong corrosion resistance capability,no coating needed for surface protection.

Typical Applications for Alnico magnet:

Widely used applications such as instruments and meters which require very stable temperature properties.

Electronic ignition systems, watt bour meters, volt-amp meters. medical instruments, industrial motors, magnetic reed switches, generators, hand tools, vending machines. alnico magnet

Magnetic properties

| Grade | Br, T | Hcb, kA/m | (BH)max, kJ/m3 | Tw,oC (max) | Structure of cast material |

| AlNi4Cu | >0.50 | >40 | >7.2 | 450 | isotropic |

| AlNiCo- Iso | 0.55-0.90 | 48-55 | 12.0-19.4 | 450 | isotropic |

| AlNiCo | 1.11-1.25 | 40-52 | 36-44 | 500 | isotropic |

| AlNiCo5Ti | 0.75-0.90 | 92-120 | 28-44 | 550 | isotropic |

| AlNiCoNb-A | 1.25-1.40 | 44-62 | 56-60 | 500 | columnar |

| AlNiCo5TiNb-A | 1.0-1.10 | 110-120 | 72-88 | 550 | columnar |

| AlNiCo5Ti-AA | 1.05-1.10 | 115-120 | 80-88 | 550 | single crystal |

| AlNiCo8Ti-AA | 0.90-0.95 | 145-160 | 64-72 | 550 | single crystal |

Note:

w - maximum working temperature

w - maximum working temperature

Shapes and sizes available (as standard):

Shapes: Blocks, cylinders, disks, rings, segments

Two or more poles

Shapes: Blocks, cylinders, disks, rings, segments

Two or more poles

Note: More complicated shapes and any magnetic configuration can be provided by special order

Standard sizes:

Blocks

| Min, mm | Max, mm | |

| W | 2 | 150 |

| T | 2 | 50 |

| L | 2 | 150 |

Cylinders

| Min, mm | Max, mm | |

| Dia | 5 | 30 |

| L | 10 | 100 |

Disks and Rings

| Min, mm | Max, mm | |

| Dia | 10 | 100 |

| h | 3< | 5/td> |

Segments

| Min, mm | Max, mm | |

| W | 20 | 100 |

| L | 10 | 150 |

| h | 3 | 8 |

.jpg)