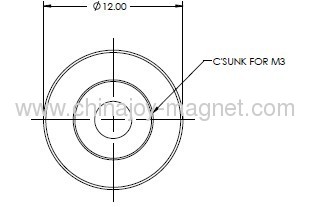

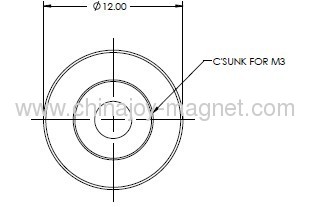

countersunk bonded NdFeB magnet

0.1~1.0 USD

| Min. Order: | 10000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Metric Ton/Metric Tons per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Rare Earth Bonded NdFeB magnet |

|---|---|

| Means of Transport: | Ocean, Air |

| Type: | Permanent |

| Composite: | NdFeB Magnet |

| Application: | Industrial Magnet |

| shape: | countersunk |

| Grade: | N35-N52,(M,H,SH,UH,EH) |

| Platings: | Ni,Zn,Au,CU |

| Place of Origin:: | Zhejiang, China (Mainland) |

| Export Area:: | All of the World |

| Cutting Tolerance:: | +/-0.05mm |

| Brand Name:: | Joy |

| Production Capacity: | 100 Metric Ton/Metric Tons per Month |

| Packing: | According to customer's requirement |

| Delivery Date: | 15-20 days |

Product Description

Physical Characteristics of bonded NdFeB Magnet

Bonded NdFeB is produced by a technique whereby a special form of NdFeB powder is blended with a plastic carrier material, die pressed aThey have lower energy products than Sintered NdFeB - in the range of 10 MGOe. The Bonded NdFeB materials are isotropic - i.e. they can be magnetized in any direction

We are specialized in manufacturing all kinds of bonded rare-earth permanent magnets, now mainly bonded NdFeB magnets as the leading products. According to the customers request, we can produce all kinds of NdFeB magnets with different complicated shapes and get them magnetized with multi-poles. The products are widely used in motor, micromotor, computer, instrument, car, motorcycle, amera, watch, HiFi, electric appliances, office automation, toy, magnetic therapy and other fields of daily life.

Bonded NdFeB Magnetsnd then heated. Parts made in this way can be of complex shapes and come off the tool with close tolerances, requiring no further finish machining.

| flexible super magnetic bonded ndfeb 1.certification:iso9001:2000 2.high quality 3.competivie prices 4.physical properties:high accuracy in size,high mechanical strength 5.manufacturing method:single-time molding and multi-poles orientation 6.surface treatments:effective surfact treatment to prevent corrosion like epoxy resin parylene-coating,no bubble no crack 7.magnetic properties:high temperature stability,the energy product is 3 times as large as ferrite,during the large-scale production,the magnetic properties are stable and the conformity is good 8.applications:mini-motors,auto motors,ai-conditioner motors,automatic controlling devices,sensors,drivers,telecom and instrument industry We have the distinct advantages in preparation, production of bonded magnets and polymer composite magnets. We have already grasped the producing technology of bonded magnets and polymer composite magnets. The magnetic products can be made into many shapes of compounding magnets like plastics, nylon, and rubber. We have the complete technology covers preparation of material, parts molding, magnetizing and inspection. |

Application More and more magnetic disturbers or mini-electronic microphones are needed in precise color enlarger, agitator, numerical control sewing machine, fixed telephone and mobile phone, and other household appliances, as well as the manufacturers of Magnetic separation and deironing equipments. It can be used in the area of micro-motors and instrumental meters for office automatic equipment, automobile industry, computer peripherals, housing appliances and all sorts of automatic equipment. It is wildly used in microwave communication technology, electrical engineering, instrumentation, meter devices, magnetic machinery, magnetic separation of transportation, magnetization, medical equipment, military rechnology, and aerospace technology. The shapes of the products can be square, bar, circular ring, tile, etc. basing on customer's requirement.  |

.jpg)