Injection Bonded Magnets Customzied

0.1~5.0 USD

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Metric Ton/Metric Tons per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Bonded magnets |

|---|---|

| Means of Transport: | Ocean |

| Type: | Permanent |

| Composite: | Bonded Magnets |

| Application: | Industrial Magnet |

| Shape: | Ring |

| Bonders: | PA6, PA12, PPS |

| Platings: | Ni,Zn,Au,CU |

| Place of Origin: | Zhejiang, China (Mainland) |

| Export Area: | All of the World |

| Brand Name: | Joy |

| Tolerance: | +/-0.05mm |

| Production Capacity: | 100 Metric Ton/Metric Tons per Month |

| Packing: | According to customer's requirement |

| Delivery Date: | 15-20 days |

Product Description

product name: Injection Bonded Magnets

We specialized in producing and supplying various magnets, bonded injection magnet, bonded injection magnets and magnetic products for more than 8 years, with our own factories in China. Our annual production capacity is over 5,000 tons about various magnets. Our products are sold over 40 countries around the world. With high quality management term, we are proud to obtain ISO9002. In all our selling products, bonded injection magnet, bonded injection magnets, bonded ferrite injection magnet shown in the brochure, we especial recommend to sell thin and small dimensions magnets. We also have a excellent team to provide various design about magnetic assembly appliance. For all, We persist in providing superior quality, competitive prices as well as prompt delivery. Based on this strong background for many years. We serve our customers sincerely while they treat us as their trustful friends. Characteristics & Application of Injection

Bonded Magnet Applications:

Copier and laser printer rolls

Permanent motor magnets (rotors & other components)

Magnetic rings for aerodynamic component

Color Monitor/TV purity convergence magnet

Bonders: PA6, PA12, PPS.

We specialized in producing and supplying various magnets, bonded injection magnet, bonded injection magnets and magnetic products for more than 8 years, with our own factories in China. Our annual production capacity is over 5,000 tons about various magnets. Our products are sold over 40 countries around the world. With high quality management term, we are proud to obtain ISO9002. In all our selling products, bonded injection magnet, bonded injection magnets, bonded ferrite injection magnet shown in the brochure, we especial recommend to sell thin and small dimensions magnets. We also have a excellent team to provide various design about magnetic assembly appliance. For all, We persist in providing superior quality, competitive prices as well as prompt delivery. Based on this strong background for many years. We serve our customers sincerely while they treat us as their trustful friends. Characteristics & Application of Injection

Bonded Magnet Applications:

Copier and laser printer rolls

Permanent motor magnets (rotors & other components)

Magnetic rings for aerodynamic component

Color Monitor/TV purity convergence magnet

Bonders: PA6, PA12, PPS.

Characteristics:Having high dimensional precision

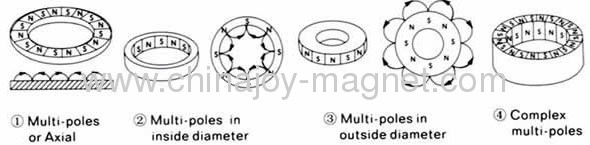

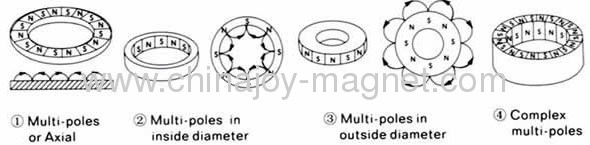

Versatile shapes and specificationImpact-resistant.advanced surface treatment technology,effectively protect.Integrated forming

Injection Bonded Magnets

Versatile shapes and specificationImpact-resistant.advanced surface treatment technology,effectively protect.Integrated forming

Injection Bonded Magnets

Bonded NdFeB magnet is made through "compression molding" or "injection molding" of the mixture of quick-quenched NdFeB magnetic powder and bonding agent.Due to its high accuracy in size, the bonded maget may be formed into magnetic components of relatively complicated shapes. Also,it features single-time molding and multi-pole orientation. The injection molded magnet has a high mechanical strength and may be molded together with other matching parts. Magnetic Properties of compression Moulding bonded NdFeB Magnets

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||