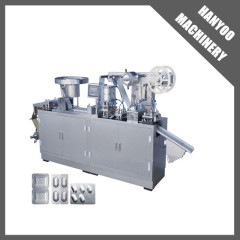

DPP-320 Capsule Blister Packaging Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wenzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Tropical Blister Packing Machine (alu-pvc-alu), Tablet Blister Packaging / Candy Blister Packing, Multi-functional Pillow-type Packing Machine, Double Soft Alu Packing/ Strip Packing Machine, Automatic Ampoule-injection Blister Packing Machine |

Product Detail

| Model No.: | DPP-320 |

|---|---|

| Means of Transport: | Ocean |

| Processing: | Blister Packaging Machine |

| Automatic Grade: | Automatic |

| Type: | Others |

| Usage: | Others |

| Packaging: | Others |

| Brand Name: | Bolin |

| Packing: | wooden case |

| Delivery Date: | 60 days |

Product Description

Features:

1) Adopting imported frequency conversion to adjust speed, whose

punching frequency is 15-60 times/min and its frequency conversion

can be adjustable

2) Chooses the length of stroke and proper punching frequency

according to different material

3) Adopting combination mode for the whole machine: putting together,

formation, and material feeding are in one section; heat sealing,

creasing and punching are in one section, which can be easy to enter

the lift and transformation workshop, lengthen the distance between

the formation and heat sealing, raise the filling rate for feeding of

foreign matter

4) The rate of finished products will be guaranteed under the high speed

running

5) Mechanism of executing drawing: composed of material delivering,

drawing and position, waste collecting

6) Enlarge its cam to lengthen the distance between up and down

running of work-site, which can make the max depth of bubble reach

26mm and satisfy the big pills and special packing requirements in

medical appliances and foodstuff trades

7) Can produce 5 boards at one time (standard 80 x 57mm), greatly

improves the packing quality

8) Can be provided with photoelectric register device to perform picture

and characters line-up

9) Can also be provided with controlling devices for pill (slice) lacking

test and waste plate rejecting system

10) Can be used as two kinds of packing: aluminum-plastic and

aluminum-aluminum, being a dual-purpose machine

11) Can also be provided with direction adjuster for hard capsules

12) Provided with PC touching push button, or human-computer

interaction, PLC programming controller

13) Fully meets all the requirements of GMP standard

14) Without punching mechanism for across side

Specifications:

1) Cutting frequency: 15-16 times/min

2) Cutting frequency: 75-300 (adjustable)

3) Max. forming depth: 26mm

4) Max. forming area: 305 x 150mm

5) Travel adjusting: 40-160mm

6) Heating plate power: 1.5kW (top), 1.5kW (bottom)

7) Hot-sealing power or aluminum-plastic: 3kW

8) Power of main motor: 2.2kW

9) Capacity of air compressor: ≥0.3m3/min

10) Size of wrapper: 320mm

11) Overall size: 3000 x 950 x 1530mm

12) Weight: 1800kg

1) Adopting imported frequency conversion to adjust speed, whose

punching frequency is 15-60 times/min and its frequency conversion

can be adjustable

2) Chooses the length of stroke and proper punching frequency

according to different material

3) Adopting combination mode for the whole machine: putting together,

formation, and material feeding are in one section; heat sealing,

creasing and punching are in one section, which can be easy to enter

the lift and transformation workshop, lengthen the distance between

the formation and heat sealing, raise the filling rate for feeding of

foreign matter

4) The rate of finished products will be guaranteed under the high speed

running

5) Mechanism of executing drawing: composed of material delivering,

drawing and position, waste collecting

6) Enlarge its cam to lengthen the distance between up and down

running of work-site, which can make the max depth of bubble reach

26mm and satisfy the big pills and special packing requirements in

medical appliances and foodstuff trades

7) Can produce 5 boards at one time (standard 80 x 57mm), greatly

improves the packing quality

8) Can be provided with photoelectric register device to perform picture

and characters line-up

9) Can also be provided with controlling devices for pill (slice) lacking

test and waste plate rejecting system

10) Can be used as two kinds of packing: aluminum-plastic and

aluminum-aluminum, being a dual-purpose machine

11) Can also be provided with direction adjuster for hard capsules

12) Provided with PC touching push button, or human-computer

interaction, PLC programming controller

13) Fully meets all the requirements of GMP standard

14) Without punching mechanism for across side

Specifications:

1) Cutting frequency: 15-16 times/min

2) Cutting frequency: 75-300 (adjustable)

3) Max. forming depth: 26mm

4) Max. forming area: 305 x 150mm

5) Travel adjusting: 40-160mm

6) Heating plate power: 1.5kW (top), 1.5kW (bottom)

7) Hot-sealing power or aluminum-plastic: 3kW

8) Power of main motor: 2.2kW

9) Capacity of air compressor: ≥0.3m3/min

10) Size of wrapper: 320mm

11) Overall size: 3000 x 950 x 1530mm

12) Weight: 1800kg

.jpg)