calcined alumina for refractories

600.0~800.0 USD

| Min. Order: | 5 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 2000tons |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Vermiculite, Perlite, Mica |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Structure: | Others |

| Standard or Nonstandard: | Standard |

| Function: | Others |

| Material: | Others |

| Brand Name: | KDH |

| Production Capacity: | 2000tons |

| Packing: | 25kg pp bag or one ton bag or as your requirements. |

| Delivery Date: | within 15 days delivery after payment. |

Product Description

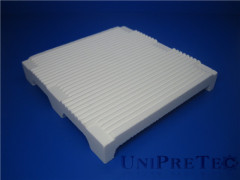

calcined alumina for refractories

1) High AL2O3 content: 95%min

2) Professional manufacturer

3) Prompt delivery

2) Professional manufacturer

3) Prompt delivery

Brown Fused Alumina is bauxite, carbon materials, iron filings in the three kinds of raw material through the melting furnace to restore the system obtained brown artificial corundum, and are thus brown corundum. Brown Fused Alumina is the main chemical ingredient AL2O3, its content is 94.5% 1 97%, and the other containing a small amount of Fe, Si, Ti and so on. Corundum because of its high hardness, toughness is good, more used as a grinding material, which is one of the most basic abrasive. Applicable to carbon steel, malleable iron and hard bronze etc. grinding. In addition, in refractory materials, chemical additives, precision casting and anti-slip material also has wider application.

Main functions:

(1) as there is high temperature, corrosion resistance, high strength properties, it poured with steel sliding gate, smelting rare metals, special alloys, ceramics, iron-smelting furnace of the lining (walls and tubes); physical and chemical containers , spark plugs, heat-resistant anti-oxidation coating.

(2) due to high hardness, wear resistance, high strength characteristics, in the chemical system, used for a variety of reaction vessels and pipelines, chemical pump parts; to do mechanical parts, various molds, such as the Roberts mold, extrusion die nozzle pencil lead, etc.; do tool, die grinding, bullet-proof material, the human body joints, sealing ring mold.

(3) corundum insulating materials, such as lightweight corundum brick, corundum hollow ball and fiber products, widely used in a variety of high-temperature kiln furnace walls and roof, both high-temperature insulation again.

item | 95 | 96 | 97 |

Al2O3 | ≥95% | ≥96% | ≥97% |

SiO2 | ≤1.2% | ≤1.0% | ≤0.8% |

TiO2 | ≤3.2% | ≤3.0% | ≤2.0% |

Fe2O3 | ≤0.3% | ≤0.2% | ≤0.2% |

CaO+ MgO | ≤0.6% | ≤0.5% | ≤0.4% |

Real demsity | ≥3.9 g/cm3 | ||

Moh's hardness | 9.0 | ||

Microhardness | 2000-2200KG/MM2 | ||

Clarseness | 8-5MM 5-3MM 3-1MM 1-0MM | ||

16# 24# 30# 36# 46# 60# 70# 80# 90# 100# 120# | |||

Fines | 180F 200F 240F 325F (Fe2O3 ≤0.50%) | ||