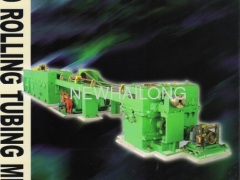

high quality cold rolling mill

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Place of Origin: | Henan |

Company Profile

| Location: | Luoyang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | MULTI-ROPE FRICTION HOIST, Support Rollers, LARGE ROTARY CEMENT KLIN, HIGH PRESSURE GRINDING ROLL, Big Teeth Circle |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Packing: | wooden case |

| Delivery Date: | 45days |

Product Description

Specifications of cold rolling mill

our product is good quality with the competitive price

our product is the best in China

our product is the best in China

Material Specification

1)Type: 1000 Series 3000Series 5000 Series 8000Series

2) Coil width: 850-1700mm

3) Thickness: 6mm-8mm

4) Thickness Tolerance: Lateral does not 2% the strip thickness

Longitudinal does not exceed 1.5% strip thickness

5) Coil Outer Diameter: Φ1800mm max

6) Coil Inner Diameter: Φ510mm (no spool)

Φ505mm (with spool)

7) Weight of Coil: 13000kg Material Requirement: no curve , telescope does not exceed 6mm/m, the crown does not exceed 3mm spool size: Φ505/Φ565*1900mm

Product Specification:

1) Coil width: 850-1700mm( no cutting edge)

800-1650mm(cutting edge)

2) Thickness: 0.2mm (min)

3) Coil Outer Diameter: Φ1800mm (max)

4) Coil weight(Max): 13000kg

5) Spool Size: Φ505/Φ565*1900mm

Main Parameter:

1) Load Force: 16000

2)Load Torque(Max); Max160 KN.M

3)Threading Speed: 18m/min(Max)

4)workroll speed: MAX 1000m/min

5) Unwinder Tension: 16500KG(Max)

6) Rewinder Tension: 16000KG(Max)

7) Work-Roll:Φ420*1900mm

8) Backup roll: Φ1100*1850mm

9) Reduction: 20%-60%

10) Forward Slip: 0-15%

11) Tension Accuracy: ±1% during constant speed operation

3% during acceleration or deceleration

12) Roll Coolant flow -rate: 5000 L/min (max)

13) Passline: +1100mm

Scope of Supply

1) Coil supply and preparation Equipments

-Coil supply car

-Storage Saddle

-Diam and width measuring device

-Coil Preparing Station

2) Decoiler ( A dual Collapsible Mandrel Decoiler)

-2 collapsible cylinder actuated

-2 double motor driven pressure

-1 outboard bearing

-Reducer supporting the 2 mandrels

-Disengageable couplings

-Primary speed reducer

- Disk Brake for safety stop

- Automatic center alignment system

3) Entry Equipment

-Threading Table with retractable opener

- Motor driven roller with wiper

-Motor driven pinch roller

-Straightening roller

-closing table

-Center guide plates

4) Mill Stand

-Pinion-stand primary speed reducer, couplings

- A set of universal drive spindles and safety sleeves

-A set of housing with wear plates,spacers and seating blocks

-A set of equipped back-up rolls

-A set of equipped work rolls

- Hydraulic units with spindle holders

-2 hydraulic screwdown cylinders

- A system of wedging for automatic adjustment of the pass line

- Extraction hood and cowling on the sand

-Recovery tanking

-spraying on the stand and pneumatic panel

- Drying tunnel with roll air wipe and strip drying

- Stand piping

-Automatic changing of back-up rolls

-Automatic changing of work rolls

5) Exit Equipment

-support of X ray gauge with withdrawal mechanism

-Press with rolls

- air wipe system

- Guiding Table

- Support Frame

- Gauge Supports

- Pass-line roller and squeeze roll

-Retractable cross shear

-Fixed covering table

- Motor driven planicim roller with motor driven pad wiper

-Retractable guiding table

- Tracking ironing roller

6) Coiler with 2 half-mandrels

- 2 cylinders actuated collapsible half mandrel

- 2 gear reduces with disengageable coupling and disk brake

-Support bed

7) Pivoting and retractable belt wrapper

8) Discharges of coils

-Cars for discharging coils on spools

- Automatic strapping station

- Weighting station

-Automatic marking device

9) Spool handling

10) Systems

- Coolant spry syetem

- Hydraulic high pressure power unit for screwdown, back-up and work roll

- Pneumatic system

- Lubrication system for the reducers

- Lubrication system by oil mist

- Centralized lubrication system

- Vapour extraction and filtration system

11) Automatic Process control system

12) Equipment and software for quality optimization gauge and flatness control