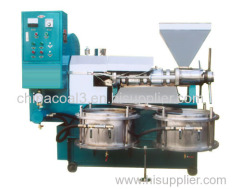

Spiral Oil expeller machinery 6YL-100

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500sets |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Oil Press, Oil Mill Manufacturer, Cold Oil Press, Hydraulic Oil Press, Small Oil Press |

Product Detail

| Model No.: | 6YL-100 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | yuanyang |

| type: | Cold & hot |

| Screw speed: | 30-40 r/min |

| gear ratio: | 15/40x15/55=1:9.78 |

| Dimension: | 1950x1300x1900 |

| Productivity: | 150-250kg/h |

| power: | 3KW |

| Production Capacity: | 500sets |

| Packing: | standard export package |

| Delivery Date: | within 5months |

Product Description

Spiral Oil expeller machinery 6YL-100

Main technical parameter of Spiral Oil expeller machinery 6YL-100

Main technical parameter of Spiral Oil expeller machinery 6YL-100

Model | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-130 | 6YL-160 | |

Screw speed | 30-45r/min | 30-40 r/min | 30-40 r/min | 28-40 r/min | 28-40 r/min | |

gear ratio | 14/42x19/57=1:6.63 | 15/40x15/55=1:9.78 | 15/34x15/55=1:9.59 | 15/38x19/48=1:7.38 | 15/38x15/52=1:8.78 | |

Dimension | 1650x1150x1750 | 1950x1300x1900 | 2050x1350x2000 | 2200x1600x2150 | 2500x1600x2500 | |

Productivity | 80-150kg/h | 150-250kg/h | 200-300kg/h | 250-400kg/h | 400-600kg/h | |

Equipped with power | Main engine | Y160L-6-5.5KW | Y160M-6-7.5KW | Y160L-6-11KW | Y180L-6-15KW | Y200L-6-18.5KW |

Vacuum pump | Y90S-4-0.55KW | Y90S-4-1.1KW | Y100L1-4-1.5KW | Y100L1-4-2.2KW | Y100L1-4-2.2KW | |

Heater | 2KW | 3KW | 3.3KW | 3.8KW | 4KW | |

Detailed description of Spiral Oil expeller machinery 6YL-100:

- Adopt micro-motor control, infrared heating, vacuum filter and three-level squeeze

- The most ideal equipment for individual

- 6YL-160oilpresses are modern products developed and improved our company newly.

- These machine adopt micro-motor control, infrared heating, vacuum filter and three-level squeeze.

- They may be used for both cold squeeze and hot squeeze and are the most ideal equipment for individual process.

Operating principle of Spiral Oil expeller machinery 6YL-100

- When oil press is on work, material enters the extruding chamber from the hopper and then moves forwards by the rotating pressing screw and is pressed.

- Under hightemperature condition in the chamber, there is quite strong friction among press screw, chamber and the oil materials.

- On the other hand, root diameter of the pressing screw carries larger from one end to the other.

- Hence when rotating, the thread not only pushes particles moving forwards but also turns them outwards as well.

- Meanwhile, particles adjacent the screw will rotate along with screw's rotating, causing every particle inside the chamber to possess different speed.

- Therefore, relative movement among particles creates neat which is necessary during manufacturing because of helping protein change property, damage colloid, increase plasticity, decrease oil's elasticity, resulting in high oil