Gold Jigger !!!energy saving mineral 670*920 jigger machine for ore separating hot sales gold ore Jigger!!!

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 100 pieces |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Ball Mill, High Efficient Sand Dryer, Crusher, Vibrating Screen, Sand Washer |

Product Detail

| Model No.: | 670×920 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Separator |

| Brand Name: | Dehong Machine |

| Certificate:: | ISO9001:2008 |

| 670×920: | energy saving mineral jigger machine |

| Gold Jigger: | jigger machine for ore separating |

| hot sales gold ore Jigger: | Dehong mining machinery from China |

| Production Capacity: | 100 pieces |

| Packing: | under customer requirement |

| Delivery Date: | according to contract |

Product Description

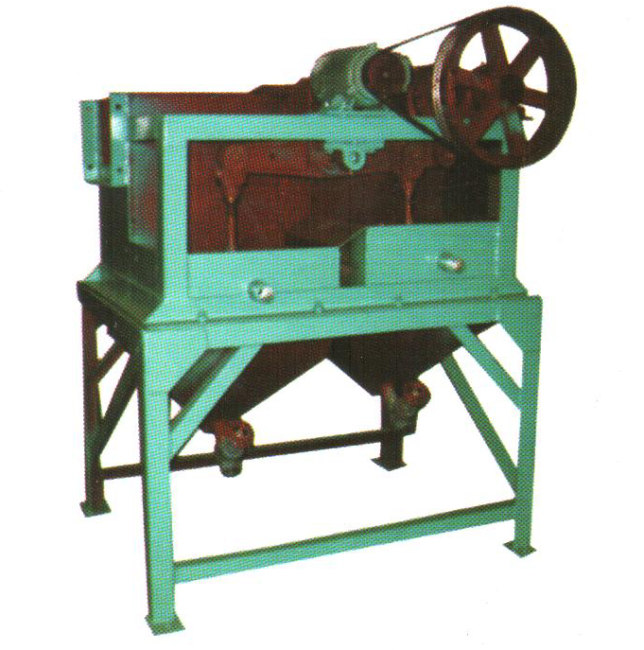

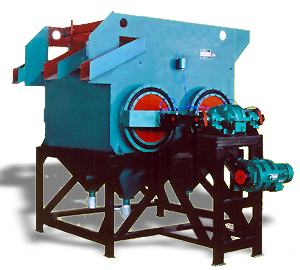

670*920 Jigger

Detail introduction

The jigger has the following advantages, such as: a wide range of selecting sizes,highcapacity, small standing area, high productivity and features ofeasy to operate andmaintenance. It is suitable in the classification ofbig density contrast ore, such as, wolfram ore, tin ore, iron ore,manganese ore, as well as ferrous metal ore carrying gold and rare metaland so on non-ferrous metal.

Introduction

Introduction

Jigger belongs to gravity beneficiation equipment, which separates mineralsbased on specific gravity. The machine mainly consists of three parts:main frame, driving device and jigging chamber. Because of its largecapacity, wide range of particle size, simple operation and maintenance,it is widely used for separating gold, tin, titanium, iron, coal andother minerals, especially manganese ore.

Jigger is classifiedinto different kinds according to raw materials, separating medium,sieve acting. Distinguished by raw materials, there are mining and coaljiggers, by separation medium, there are water and wind jiggers, bysieve motion, there are fixed Technical parameters

Application of jigger

Application of jigger

This machine is widely applied to gravity separation for a lot of metals

and metal minerals such as wolfram, tin, placer gold, hematite, limonite,

manganese, titanium, antimony, lead, tantalum, niobium, etc.

Working principle

Working principle

The beneficiation process of jigger is divided into two stages: sorting and separation. The stage of sorting is to

layer the ore particles according to th

eir density, which is affected by the properties of ores and operational rules, and is also the premise to the next

stage of separation. The separation st

age is a course of discharging, which is decided by the distribution of layers, the precision of test method for stack

thickness, reasonableness of disc

harging pattern, control system, etc.

The technical parameter of 670*920 Jigger

Model: 670*920Chamber number :2 Chamer area(m3): 1.44 Feeding size(mm): 4-8

Capacity(t/h): 7-10Stroke(mm):18-24Motor Model: -Motor Power(kw): - Weight(kg):-