High quality Vibrating feeder with ISO9001:2008 certificated

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 100 pieces |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Ball Mill, High Efficient Sand Dryer, Crusher, Vibrating Screen, Sand Washer |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Brand Name: | Dehong |

| Dehong: | New mining machinery |

| GZD series machine: | High quality Vibrating feeder with ISO9001:2008 certificated |

| made in China: | High quality Vibrating feeder |

| Production Capacity: | 100 pieces |

| Packing: | Customer requirements |

| Delivery Date: | According to the contract with the funds to decide |

Product Description

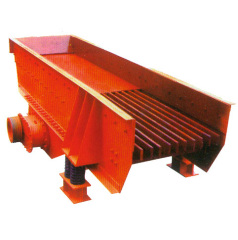

High quality Vibrating feeder with ISO9001:2008 certificated

Brief introduction of Vibrating Feeder:

The Vibrating Feeder (Vibratory feeder) is mainly used in feeding materials before coarse crushing. Our GZD series machine can put the block or granule materials from the material storage into the charging device in time evenly and continuously. Therefore, it can realize even feeding for crushers in sandstone production line and make rough screening of materials. The vibrating feeder is widely used to match the crushing and sieving equipments in many industries including metallurgy, coal mine, mineral dressing, building material, chemical, grinding, etc.

Working Principle of Vibrating Feeder:

There are two eccentric shafts rotating at high speed at the same time from opposite directions, thus the strong centrifugal force is formed. The component forces of centrifugal force along the vibrating direction will always overlap each other, then counteract with that of vertical force from vibrating direction, then exciting force along single direction is formed to drive the feeder vibrate along straight line. When materials are fed into the feeder, they may be thrown up and move like para curve, then fall down. The materials will move forward on the slope surface of the feeder.

Features of Vibrating Feeder:

1) Smooth vibration

2) Reliable working

3) long-life, low noise, low power consumption

4) Excellent performance, no flushing phenomenon of materials

5) Easy maintenance and low operating cost

Main technical parameters of Vibrating Feeder:

Model | Max. Input Size (mm) | capacity (t/h) | MotorPower (KW) | OverallDimension ( mm) | Weight (Kg) | Size of Funnel (mm) |

GZD-900×3000 | 400 | 80-120 | 6 | 3110×1800×1600 | 2100 | 900×3000 |

GZD-950×3800 | 500 | 120--210 | 6 | 3850×1950×1630 | 2300 | 950×3800 |

GZD-1100×4900 | 580 | 160-320 | 11 | 5200×2050×1700 | 4200 | 1100×4900 |

GZD-1200×4900 | 650 | 200-430 | 15 | 5200×2150×1700 | 4500 | 1200×4900 |

GZD-1300×6000 | 900 | 450-600 | 22 | 5200×2350×1750 | 6500 | 1300×6000 |