furnace water cable

1000.0~800000.0 USD

| Min. Order: | 1 Pound |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 pc/year |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Wire Rope, Drill Pipe, Dill Collar, Casing Tube |

Product Detail

| Type: | Furnace |

|---|---|

| Processing Type: | Machining Equipment |

| Brand Name: | seec |

| Production Capacity: | 100 pc/year |

| Packing: | independent packing |

| Delivery Date: | 60days |

Product Description

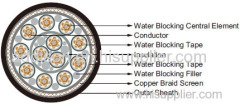

Water Cooled Cable , Water-cooled Cable for Induction Furnace

Water-cooled cable is a hollow-pass water special cable for high current heating equipment; it consist of electrodes (cable head), wire, outer sheath tube of three parts.

High-quality water-cooled cable with electrodes made of overall copper rod milling, surface with passivation or tin processing; the conductor wire use of enameled wire, which woven by the CNC winding machines, softer, bending radius is small, corrosion-resistant rust-proof, using long life; outer sheath governing use of strengthening layer of synthetic rubber tube, withstand high voltage. The copper tube and the electrode clamp use red copper fixed on the professional equipment by cold extrusion, fastening, sealing is good, not easy to leak.

Water-cooled cable performance requirements

1. Water-cooled cable outer sheath tube resistance to breakdown voltage V same or higher than 2300V.

2. Water-cooled cable outer sheath tube working pressure-resistant P same or higher than 0.6Mpa.

3. Outer sheath tube and the electrode interfaces of the cooling water without leakage.

4. Software conductor wire and electrode in a dedicated cold extrusion fastening device.

5. 200mm2 Nominal cross-sectional area of the pilot pull is 15KN, on this basis, the water-cooled cable nominal cross-sectional area for each additional 100mm2, the test tension value should be a corresponding increase, plus 5KN.

6. The maximum surface temperature rise of water-cooled cable (including connections) is not greater than 40K.

.jpg)

.jpg)