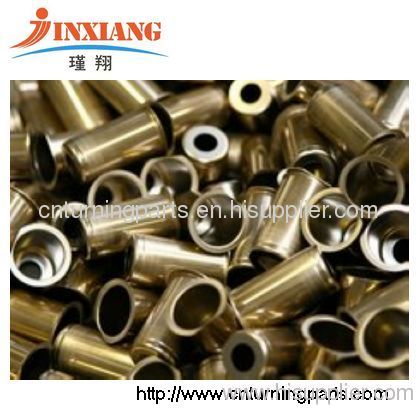

copper CNC turning parts

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 5000000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | CNC Precision Turning Parts, Stainless Steel Turned Part, Welded Parts, CNC Turned Component, Metal Stamping Parts |

Product Detail

| Model No.: | JXBR01 |

|---|---|

| Means of Transport: | Ocean, express, Air, Land |

| Tolerance: | 0.005mm |

| Surface Roughness: | Ra0.4-6.3 |

| treatment: | plating(Zinc,Chrome,Nickel...) |

| processing: | turning,drilling,knurling,etc |

| Brand: | Jinxiang |

| Place of Origin: | Zhejiang China(mainland) |

| Production Capacity: | 5000000pcs/month |

| Packing: | Polybag and carton |

| Delivery Date: | 25 days |

Product Description

Ningbo Jinxiang Industry Co., Ltd is specialized in manufacturing various hardware fittings. Our products range are CNC parts,machining parts,turning parts,precision parts,stamping parts,which are mainly apply to Electrical appliance,Furniture,Toy etc.. Furthermore, we adopt the advanced production equipment. We have larger production scale and better production capability.

Products range : processing all kinds of aircraft parts, automobile parts, electronic components , precision mechanical,precision parts, machining parts, spare parts, precision machining etc…

Work range:

CNC Turning work range:φ0.5mm-φ300mm*750mm

CNC milling work range:510mm*1020mm*500mm

External diameter: 2 and 500 mm

Tolerance: 0.005mm

Surface Roughness:Ra0.4-6.3

Capacity:0.5mm~1020mm

Software:Pro/E,Auto CAD,PDF,CAD

Material:steel, iron, stainless steel, aluminum, copper, plastic etc

Surface treatment: heat treatment; aluminum alloy; zinc/ nickel/ chrome/ plated, spray paint, copper satin, anodized; power coating etc

Applications : Car parts ; Medical devices ; optical parts ; Electric sheets ; Industrial ; Medical ; Power / Energy ; etc…

Manufacturing Process

Design Mould→confirm samples→purchase material→ blanking→ punching→ welding/bending→ forming→surface treatment→ Inspection→ assemble products→Package

Main Process:CNC machining,CNC lathe milling,ATO lathe processing,Wire-cut, electric discharge master(EDM), CNC machining center, high speed punch, bending machine, injection machine etc,and CMM, tool microscope, projector, height gauge to assure good quality high quality.

Equipments:

a) CNC Machining Center(HAAS)

b) CNC Lathes

c) CNC Milling Machines

d) Punching Machines

e) Precision Cutting Machines

f) Argon Welding Machines

g)NC Bending Machine

h)EDM

g)driller

Packaging & Delivery

1.Standard export package, water-proof, damp-proof and so on

2.Packagings: Poly bag and carton, 0.5-15kgs/carton ,Pallet or container

Inspection

QC System: 100% inspection before shipment

Place of Origin: China (mainland)

Port:Ningbo,China

Terms of Payment : 30% T/T in advance, the balance before shipment

Shipment

1)0-100kg: air freight priority,

2)>100kg: sea freight priority,

3)As per customized specifications.

Information to inquiry

1.Type of material and hardness needed

2.Quantity of the product.

3.Part application

4.The tolerances of the product

5.Drawings, samples or pictures with details

6.Target price if you have one