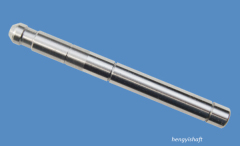

high precision machined motor shafts

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10000000 pcs |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | CNC Precision Turning Parts, Stainless Steel Turned Part, Welded Parts, CNC Turned Component, Metal Stamping Parts |

Product Detail

| Model No.: | JXS011 |

|---|---|

| Means of Transport: | Ocean, express, Air, Land |

| material: | steel 430 |

| tolerance: | +/-0.004mm |

| diameter: | 2-80mm |

| Length: | Customed |

| Hardness: | HRC20-58 |

| brand: | Jinxiang |

| roughness: | Ra0.4 |

| Production Capacity: | 10000000 pcs |

| Packing: | polybag,carton |

| Delivery Date: | 15 days |

Product Description

Jinxiang offers a wide range of precision steel shafts. Our customers can choose between more than 45 types. Parameter like diameter, length, tolerance and shaft end shape can be configured matching to your application

Motor shaft, Precision shaft, Micro Shaft, Rotor shaft, Pump shaft, Pins, Hinge pin, Metal part, Mechanical precision part.

1) Material: Carbon steel, Stainless steel, brass or as per customer's requirements.

2) Diameter: 0.3-17mm, tolerance: +/-0.001mm

3) Roundness: 0.001mm

4) Roughness: Ra0.04

5) Straightness: 0.001mm

6) Length: Max. 1000mm

7) Heat treatment: Point hardening, quenching hardening

8)Surface treatment: Zinc plating, nigrescence, chrome plating, nickel plating etc.

Motor shaft, Precision shaft, Micro Shaft, Rotor shaft, Pump shaft, Pins, Hinge pin, Metal part, Mechanical precision part.

Specifications

1,According to drawing,our engineers and technicians analyse processing technics to generate procedures and then make the working plan for the shaft.

2,With technicians around,well-trained operators follow the working plan work on each procedure. Use Digital control lathes,polishing machines, milling machines, stamping machines,high-frequency induction quenching machines, etc.

3,Strict and experienced QC team inspecting on every working procedure.Use high quality test equipment as hardometer,image survey meter,etc.Also run tests like metallographic analysis.

4,After FQC,we pack goods carefully.

Motor shaft, Precision shaft, Micro Shaft, Rotor shaft, Pump shaft, Pins, Hinge pin, Metal part, Mechanical precision part.

Motor shaft, Precision shaft, Micro Shaft, Rotor shaft, Pump shaft, Pins, Hinge pin, Metal part, Mechanical precision part.

Motor shaft, Precision shaft, Micro Shaft, Rotor shaft, Pump shaft, Pins, Hinge pin, Metal part, Mechanical precision part.