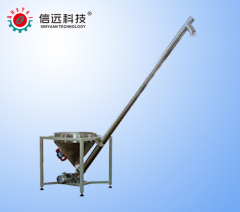

LS Screw conveyor

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T, WU |

| Supply Ability: | 100set/sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | LS |

|---|---|

| Means of Transport: | Ocean, Land |

| Production Capacity: | 100set/sets per month |

| Packing: | wooden case or standard export packing |

| Delivery Date: | 7~10days |

Product Description

Product Description:

1.Small size,high output

2.Good sealing.

3.Reliable.

4.Low cost.

Detailed product introduction:

Screw conveyor is through the rotation of screws to continuous conveying material, it is suitable for conveying flour, corn, cement, fertilizers, ash, sand and gravel, coal, small materials, such as coal. Due to the effective circulation in the area is small, screw conveyor is unfavorable to transported, viscous metamorphic easy to agglomerate materials.

Screw conveyor can set as level or tilted conveying form (GX Angle less than 20 °, LS spiral less than 15 °) if you need to change to transportation, should make a special order. Working environment temperature range is usually-20-80 ℃.

Work environment temperature is usually-20 to 40 ℃, the temperature of the conveying material is generally-20-200 ℃

LS spiral screw conveyor appropriate level and little inclination to decorate, dip Angle to no more than 20 ° advisable;

If you have special request, we can design and manufacture according to your special need.

Features:

Sealing well ,easy maintenance,simple structure,small size,reliable, low cost,etc.

Application:

Screw machine is widely used in various industries, such as building materials, chemical industry, electric power, metallurgy, mine, coal, grain etc applies level or tilted transportation powder, granular and small lump materials, such as coal, ash and slag, cement, grain and other materials, and less than 200 degrees Celsius temperature. Not suitable for conveying screw machine is bad, big viscosity, nutrition materials. In the concrete mixing station, screw conveyor obtain the biggest role.

echnical parameters:

| LS Srew conveyor | ||||||

| Model | Spiral Diameter (mm) | Pitch(mm) | Spiral Rotaticnal Speed(r/min) | Max Transport Capasity(m3/h) | Motor Power(kw) | Admission Biggest Gradient(°) |

| LS100 | 100 | 100 | 140 | 2.2 | 2.2-18.5 | ≤20 |

| LS125 | 125 | 125 | 125 | 4 | ||

| LS160 | 160 | 160 | 112 | 8 | ||

| LS200 | 200 | 200 | 100 | 11 | ||

| LS250 | 250 | 250 | 90 | 22 | ||

| LS315 | 315 | 315 | 80 | 34 | ||

| LS400 | 400 | 355 | 71 | 64 | ||

| LS500 | 500 | 400 | 63 | 95 | ||

| LS630 | 630 | 450 | 50 | 150 | ||

| LS800 | 800 | 500 | 40 | 210 | ||