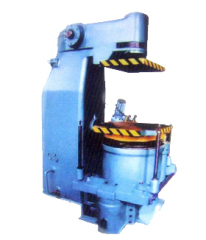

foundry moulding machines

| Min. Order: | 1 set |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | large scale manufacturer |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Foundry Machinery Molding Machine, Foundry Machinery And Equipment, Sand Blast Machine, Steel Surface Cleaning, The Core Making Equipments |

Product Detail

| Model No.: | Z14 series |

|---|---|

| Means of Transport: | Ocean |

| main structure a: | ram-jolt cylinder block |

| main structure b: | ram-jolt piston |

| main structure c: | pressure piston |

| main structure d: | buffer mechanical spring |

| main structure e: | drawing hydro-cylinder piston |

| Production Capacity: | large scale manufacturer |

| Packing: | wooden case paking and FCL |

| Delivery Date: | in stock |

Product Description

What is the jolt squeeze moulding machine?

Jolt squeeze foundry moulding machine to vibrated mold further compaction, can get the top and bottom of tight sand mold. Commonly used is micro shock compacting moulding machine (see chart micro shock compacting moulding machine), using table whereabouts and floating shock iron collided, microtremor tight sand, again carries on the compaction. Micro shock is high frequency (500 ~ 1000 times/min), small amplitude (5 ~ 25 mm) vibration instead of shock type moulding machine of low frequency (60 ~ 120 times/min), the large amplitude vibration. This kind of moulding machine made of sand mold good quality of basic requirements, is also lower.

the technical specification of foundry moulding machine

Qingdao Xicheng Foundry Machinery CO.,LTD foundry moulding machine in stock.

Jolt squeeze foundry moulding machine to vibrated mold further compaction, can get the top and bottom of tight sand mold. Commonly used is micro shock compacting moulding machine (see chart micro shock compacting moulding machine), using table whereabouts and floating shock iron collided, microtremor tight sand, again carries on the compaction. Micro shock is high frequency (500 ~ 1000 times/min), small amplitude (5 ~ 25 mm) vibration instead of shock type moulding machine of low frequency (60 ~ 120 times/min), the large amplitude vibration. This kind of moulding machine made of sand mold good quality of basic requirements, is also lower.

the technical specification of foundry moulding machine

Item | Unit | Z148CW |

Max dimension of flask | mm | 800×630×320 |

Worktable dimension | mm | 900×730 |

Air pressure | Mpa | 0.6 |

Compressive strength | KN | 120 |

Jolting load | KN | 5.5 |

Compacting stroke | mm | 195 |

Draw stroke | mm | 320 |

Distance between worktable to pressure head | mm | 350-680 |

Productivity | Mould/h | 40-60 |

.jpg)

.jpg)