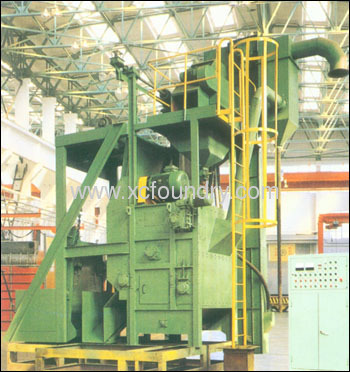

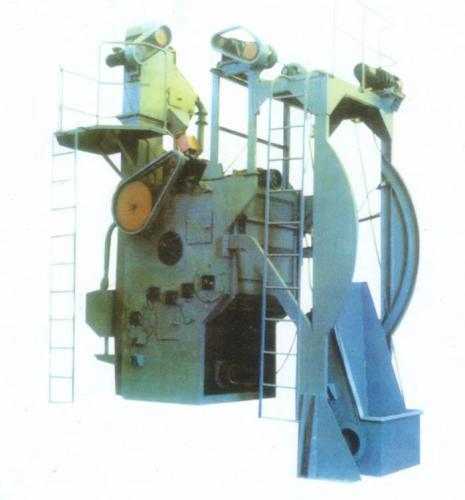

tumble belt shot-blast equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | LARGE |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Foundry Machinery Molding Machine, Foundry Machinery And Equipment, Sand Blast Machine, Steel Surface Cleaning, The Core Making Equipments |

Product Detail

| Model No.: | Q3210 |

|---|---|

| Means of Transport: | Ocean |

| Automation: | Automatic |

| Certification: | ISO 9001:2000 |

| Brand Name: | XICHENG |

| Production Capacity: | LARGE |

| Packing: | WOODEN |

| Delivery Date: | 25-30DAYS |

Product Description

tumble belt shot-blast equipment

more photos for tumble shot blasting machine

Q32 tumble shot blasting machine

Q3210 tumble shot blasting machine

Q326 tumble shot blasting machine

Q3220 tumble shot blasting machine

Q326C tumble shot blasting machine

Our Q32 tumble shot blasting machine is used for surface contaminant removal or strengthening treatment of each kind of small and medium castings, forgings and workpieces. A single shot blasting machine can be used independently. In addition, several units can be used in combination with continuous conveyor and other auxiliary equipment, forming a whole cleaning line.

Our tumble shot blasting machine offers reasonable structure, low energy consumption and high efficiency. The blast chamber is equipped with wear protection plate on the inner wall to avoid punctures due to shots at a high velocity. The rubber belt conveyor allows easy tumbling of workpieces and has many shot leakage holes for the cycle of balls. The Q360 blast wheel used in our blasting equipment is an efficient product made using technology from Japan. The wheel blades are durable, easy to assemble and disassemble. The special shot distributor design contributes to low power consumption and high shot flow rate. To provide a better work environment for operators, our tumble shot blasting machine adopts double dedusting. Large particles will settle first based on the inertia principle, and others will be filtered by the bag type dust collector, which greatly improves the dedusting efficiency.

tumble shot blasting machine is used for surface cleaning, rust removing and surface intensification of each kind of middle and small scale casting , forging job. It is suitable for different production scale, can be stand-alone used and many units can also be used in conjunction with the continuous conveyor components, composing the production of clean-up lines.

1. The impeller head is composed of blast wheel, the structure is simple and durable.

2. BE type segregator is very efficient and it can protect blast wheel.

3. The bag dust filter can greatly reduce air pollution and improve the work environment.

4. Abrasion resistant rubber belt lighten the collision of work pieces, and lower the noise.

5. This machine is controlled by PLC, the operation is easy and reliable

Ifyou are interested in tumble shot blasting machine ,pls feel free to contact with ms snow .you will receive our prompt reply.

specification for tumble shot blasting machine

specification for tumble shot blasting machine

type parameter | Q326 | Q3210 | QR3210 |

Producitivity (T/H) | 0.6-1.2 | 3-5 | 1.5-2.5 |

Loading weight (KG) | 200 | 800 | 600 |

The maximum weight of one piece (KG) | 10 | 15 | 30 |

Diameter of roller (MM) | 650mm | 1000mm | 1000mm |

Available capacity (M3) | 0.15 | 0.4 | 0.3 |

Blasting capacity (KG/MIN) | 100 | 250 | 250 |

Dedusting air volume (M3/H) | 2200 | 6000 | 5000 |

Power consumption (KW) | 12.6 | 32.6 | 24.3 |

Appearance dimension (MM) | 3681*1650*5800 | 3644*2926*5856 | 3972*2600*4768 |

Total weight of machine (KG) | 2340kgs | 5843kgs | 7400kgs |

more photos for tumble shot blasting machine

Q32 tumble shot blasting machine

Q3210 tumble shot blasting machine

Q326 tumble shot blasting machine

Q3220 tumble shot blasting machine

Q326C tumble shot blasting machine

.jpg)