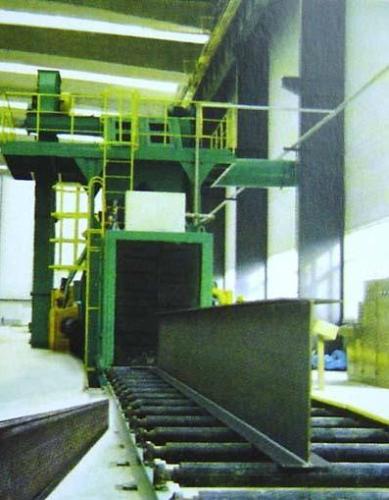

Q698 steel profiles shot blasting machine

| Place of Origin: | Shandong |

|---|

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Foundry Machinery Molding Machine, Foundry Machinery And Equipment, Sand Blast Machine, Steel Surface Cleaning, The Core Making Equipments |

Product Description

Q698 steel profiles shot blasting machine

Our Q698 steel profiles shot blasting machine is a piece of shot blast equipment which can perform preheating, shot blasting, paint spraying and drying processes. Q698 steel profiles shot blasting machineis mainly used for removing surface rust, contaminants and spraying paint onto the surface of steel boards, steel profiles and structural components in industries such as shipping, automobile, motorcycle, bridge, machinery, etc.

The roller bed in the blast chamber as well as front and rear auxiliary chambers is manufactured of steel pipes which offer thick wall and have undergone quenching and tempering treatment. In addition, the roller bed is provided with easy to replace high chromium abrasion resistant steel sheath. This helps guarantee the high rigidity, strength and long service life of roller shaft.

Q698 steel profiles shot blasting machine achieves accurate, effective paint spraying. A workpiece width measuring device is installed at the inlet of the spray booth. The PLC controls paint spraying operations of the spray gun according to the measured data. In this way, the paint squeezed out of the nozzle can be effectively sprayed onto the workpiece surface, which helps improve paint utilization.

To ensure reliable control, our company uses OMRON programmable logic controller (PLC) and inverter. Q698 steel profiles shot blasting machine is designed with auto / manual switch. Therefore, our steel profile shot blasting machine can automatically operate according to the preset programs, and it can also be manually controlled to facilitate equipment adjustments

parameter | Q698 | Q6912 | Q6915 | Q6920 | Q6925 | Q6930 | Q6940 |

The effective cleaning width(mm) | 800 | 1200 | 1500 | 2000 | 2500 | 3000 | 4000 |

The room feed-in size | 1000*400 | 1400*400 | 1700*400 | 2200*400 | 2700*800 | 3200*800 | 4200*400 |

The length of cleaning workpiece(mm) | 1200-12000 | 1200-1600 | 1200-12000 | 1200-12000 | 3000-12000 | 2400-12000 | 4500-18000 |

The speed of wheel conveyer(m/min) | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 |

The thickness of cleaning steel sheet (mm) | 3-60 | 3-60 | 1.5-60 | 3-60 | 3-60 | 3-110 | 4.5-100 |

Steel spectification (mm) | 800*300 | 1000*300 | 1500*300 | 2000*300 | 2500*700 | 3000*700 | 4000*300 |

The quantity of shot blasting (kg/min) | 4*180 | 4*250 | 4*250 | 6*250 | 6*250 | 6*360 | 8*360 |

The first enclosed quantity (kg) | 4000 | 4000 | 4000 | 4500 | 4500 | 8000 | 11000 |

Roll brush adjusting height (mm) | 200 | 200 | 350 | 450 | 600 | 850 | 900 |

Air capacity(m3/h) | 22000 | 17560 | 19000 | 19550 | 27758 | 28050 | 38000 |

Exterior size (mm) | |||||||

Total power (kw) | 90 | 78.3 | 113.5 | 156.6 | 204.8 | 224.55 | 293.6 |

.gif)

.jpg)